Collections of old holiday greetings, typically pre-1970s, sold in their original packaging, represent a tangible link to past celebrations. These assortments often include multiple cards of similar design or theme, reflecting the aesthetic and social customs of a particular era. For example, a collection might contain depictions of snow-covered villages common in the 1950s, or religious imagery prevalent in earlier decades.

The significance of these preserved holiday ephemera lies in their capacity to evoke nostalgia and provide insight into historical trends in design, printing, and societal values. Examining the artwork, materials, and messages conveyed offers a glimpse into the cultural landscape of previous generations. Furthermore, acquiring these items can provide a unique and aesthetically pleasing means of decoration and personal connection to the past.

The subsequent sections will delve into specific aspects relating to the identification, valuation, preservation, and sourcing of these festive keepsakes.

Tips for Acquiring and Maintaining Holiday Ephemera Collections

Careful consideration is required when engaging with collections of festive, antique correspondence. The following guidelines offer practical advice for both novice and experienced collectors.

Tip 1: Assess Condition Thoroughly: Examine each piece for discoloration, tears, creases, or fading. The item’s value decreases proportionally to the extent of degradation. Prioritize selections in pristine, or near-pristine, condition.

Tip 2: Verify Authenticity and Era: Research the printing styles, paper types, and postal markings associated with different periods. Comparing details with reputable sources can help determine the genuine nature and age of a particular card or package.

Tip 3: Consider Rarity and Subject Matter: Items featuring unusual designs, specific artists, or themes that resonate with contemporary interests (such as mid-century modern aesthetics) may command higher prices. Scarcity directly impacts value.

Tip 4: Investigate Provenance Where Possible: Information about the card’s origin or previous owners can enhance its historical significance and, consequently, its desirability. Documented histories add demonstrable worth.

Tip 5: Employ Proper Storage Techniques: To prevent deterioration, keep items away from direct sunlight, excessive humidity, and extreme temperature fluctuations. Acid-free archival sleeves or boxes are recommended for long-term preservation.

Tip 6: Handle with Utmost Care: Always use clean, dry hands or archival gloves when handling fragile paper materials. Avoid bending, folding, or applying pressure that could cause damage.

Tip 7: Research Market Values Before Purchasing: Compare prices of similar examples available through auction sites, antique dealers, and collector communities. A clear understanding of current market rates prevents overpayment.

Following these recommendations enables collectors to make informed decisions, safeguard their investment, and ensure the longevity of these irreplaceable pieces of history.

The following sections provide further insight into specific historical styles, conservation strategies, and relevant resources for enriching one’s engagement with this festive and collectible medium.

1. Authenticity

The validity of holiday ephemera is critical in determining its value and historical significance. Falsified or misrepresented antique correspondence lacks the inherent worth of genuine pieces, misleading collectors and distorting market values. Establishing authenticity often involves careful examination of printing techniques, paper composition, and historical postal markings, which can definitively link the item to a specific era. A genuine boxed collection from the 1940s, for example, would exhibit characteristics consistent with the printing technologies and materials available at that time, such as specific ink types or paper stock.

Moreover, the presence of original manufacturer markings and packaging details provides compelling evidence of legitimacy. Counterfeit items frequently lack these distinguishing features or display inconsistencies in typography, design, or overall construction. For instance, an original box would feature printing styles and branding consistent with the era of production, while a reproduction might exhibit anachronistic fonts or inaccurate representations of the original manufacturer’s logo. Examination by experts and cross-referencing with historical catalogues are essential steps to identify a piece. These are vital aspects to ascertain that one has a valid, true, and correct collectible for their investment.

In conclusion, verifying the genuine origin of the items within the box is vital for preservation of value and accurate historical interpretation. Vigilance in scrutinizing details and seeking expert verification mitigates the risk of acquiring misrepresented goods and ensures the integrity of collected keepsakes.

2. Condition

The physical state of boxed antique holiday correspondence significantly impacts its desirability and financial worth. Preservation quality serves as a primary determinant of an item’s overall value within the collector’s market. Factors that influence this evaluation are multifaceted and require careful consideration.

- Paper Quality and Degradation

The composition of the paper stock used in older holiday greetings often renders them susceptible to yellowing, embrittlement, and foxing (small brown spots caused by oxidation). Cards stored improperly may exhibit extensive discoloration, tears, or creases. The extent of these defects directly correlates with a reduction in the item’s assessed price. Preserving the original paper integrity is therefore crucial.

- Ink Fading and Bleeding

Exposure to sunlight or moisture can cause the inks used in vintage prints to fade, bleed, or run, diminishing the clarity and vibrancy of the artwork. Certain ink types are more prone to deterioration than others. Furthermore, improper storage can cause the inks to transfer onto adjacent cards within the box. Cards with significant discoloration or blurred imagery are less desirable to collectors.

- Box Integrity and Completeness

The original packaging is integral to the value of the collection. A complete box, free from significant damage such as tears, dents, or water stains, enhances the item’s historical appeal and marketability. The presence of any original inserts, such as tissue paper or promotional materials, further increases its worth. Missing or damaged boxes detract significantly from the collection’s overall value.

- Handling and Storage Marks

Evidence of careless handling, such as fingerprints, smudges, or adhesive residue, can diminish the visual appeal and long-term preservation of the items. Similarly, signs of improper storage, such as mold growth or pest damage, can irreversibly compromise the physical integrity. Collectors prioritize items that demonstrate minimal signs of previous use and have been maintained in appropriate archival conditions.

In conclusion, meticulous evaluation of physical attributes is vital when appraising the worth and longevity of antique festive greetings and their boxed enclosures. Addressing these areas of concern ensures that collections maintain an elevated status within the market.

3. Rarity

The infrequent existence of specific antique holiday greetings in their original packaging amplifies their value within the collector community. Scarcity is a primary driver of desirability and, consequently, market value.

- Limited Production Runs

Certain designs or manufacturers may have produced limited quantities of particular festive correspondence. Short print runs, often due to experimental printing techniques or niche market appeal, resulted in fewer examples entering circulation. A boxed set from a small, regional printer, for instance, would be significantly rarer than mass-produced offerings from larger national companies. The fewer the original print run, the higher the value.

- Survival Rate of Complete Sets

The passage of time inevitably reduces the number of complete, boxed sets available. Damage, loss, or dispersal of individual cards from the original assortment contributes to the increasing scarcity. Sets where every card is present and the packaging remains intact are highly sought after. For example, a box designed with a specific number of cards where all cards are present elevates its desirability.

- Unique or Unusual Designs

Holiday greetings featuring unconventional artwork, experimental printing methods, or regionally specific themes command a premium due to their distinctiveness. Cards showcasing celebrity endorsements, unusual materials (such as fabric or metal embellishments), or designs reflecting specific historical events can be particularly difficult to locate. A card incorporating silk screening, for example, can be rare and sought after by collectors.

- Historical Significance and Context

Correspondence linked to notable historical events, figures, or social movements may acquire increased rarity and historical importance. A boxed set that had provenance with a famous person or event might be highly sort after. The historical impact on the collector drives the value of such cards.

The limited availability of these items is a crucial factor in the valuation and desirability. Collectors often prioritize examples exhibiting a combination of these scarce attributes, contributing to a dynamic and nuanced market for these historical artifacts.

4. Artwork

The visual elements constitute a critical aspect of antique holiday correspondence, significantly influencing its historical and aesthetic value. The artistry displayed on these cards reflects prevailing cultural trends, printing technologies, and artistic styles of their respective eras.

- Illustrative Styles and Techniques

The specific artistic techniques employed on holiday correspondence vary widely depending on the period of production. Early examples may feature hand-painted illustrations or intricate engravings, while later cards exhibit characteristics of lithography, chromolithography, and offset printing. Each technique imparts a distinct visual quality and level of detail. For instance, a card from the early 20th century might showcase the soft, blended colors achievable through chromolithography, while a mid-century example could feature the bolder, graphic style associated with offset printing. The artistry employed informs the value of the collectible.

- Subject Matter and Iconography

The subject matter depicted on these cards provides insights into the social customs, religious beliefs, and cultural values of past generations. Common themes include winter landscapes, scenes of domestic life, religious iconography, and depictions of Santa Claus. The representation of these themes evolved over time, reflecting changing societal norms and artistic conventions. A card from the Victorian era might feature sentimental depictions of family gatherings, while a post-war example could showcase idealized suburban scenes. The content is essential in documenting historical context.

- Use of Color and Typography

The color palettes and typographic styles used on holiday correspondence contribute significantly to its overall aesthetic appeal and historical context. Early cards often feature muted color schemes and ornate typography, reflecting the tastes of the period. Later examples may incorporate brighter, more saturated colors and modern fonts. The evolution of color printing technology is evident in the transition from hand-tinted cards to those produced with full-color printing processes. Typography also plays a role. Styles and layout are significant markers of its era.

- Artist Attribution and Signature

In some instances, holiday correspondence features artwork attributed to specific artists or illustrators. Signed cards, or those with identifiable artistic styles, can command higher prices among collectors. The presence of an artist’s signature adds provenance and enhances the historical significance of the item. Identifying the artistic influence adds value to the collectibles.

Therefore, assessing the artwork provides valuable insights into the cultural, historical, and artistic context of antique festive greetings. Evaluating the aspects discussed enables both casual enthusiasts and seasoned collectors to appreciate and value these artifacts.

5. Subject Matter

The thematic content represented on antique festive correspondence provides a window into the cultural values, societal norms, and historical context of the eras in which they were created. Examining subject matter offers valuable insights into the evolution of holiday traditions and aesthetic preferences.

- Religious Symbolism

Early holiday greetings frequently incorporated religious iconography, such as depictions of the Nativity, angels, and biblical scenes. These images reflected the central role of Christianity in holiday celebrations and served as expressions of faith. An example would be cards depicting the Three Wise Men, symbolizing reverence and the spiritual essence of Christmas. The presence or absence of such symbolism provides a measure of prevailing religious sentiment during specific periods.

- Secular Imagery and Festive Traditions

As societal attitudes evolved, secular imagery gained prominence in holiday correspondence. Depictions of Santa Claus, winter landscapes, snow-covered villages, and scenes of domestic merriment became increasingly common. These themes emphasized the celebratory and convivial aspects of the holiday season. For example, cards showcasing families gathered around a Christmas tree or skaters on a frozen pond reflected idealized visions of domestic life. The prevalence of these images signifies the shifting focus towards secular celebrations.

- Patriotic and Nationalistic Themes

During periods of war or national crisis, holiday greetings often incorporated patriotic symbols and messages of national unity. Depictions of soldiers, flags, and national emblems served to bolster morale and promote a sense of collective identity. For example, cards produced during World War II might feature imagery of soldiers alongside messages of hope and resilience. The inclusion of patriotic themes underscores the impact of historical events on holiday traditions.

- Humorous and Sentimental Content

Many antique holiday greetings employed humor or sentimental expressions to convey holiday wishes. Comic depictions of holiday mishaps, witty greetings, and touching messages of love and friendship were common. These elements served to create a sense of levity and emotional connection. Cards portraying a comical mishap, such as Santa Claus stuck in a chimney, would reflect a lighthearted, fun tradition. These sentiments provide a sense of the emotional landscape of their time.

The themes found within collections of antique festive greetings offer a comprehensive understanding of the cultural and historical influences shaping holiday celebrations. By examining the subject matter, one gains valuable insight into the values, beliefs, and social norms that characterized past eras.

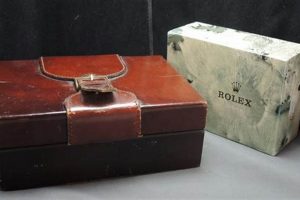

6. Packaging

The original containers represent a crucial element in evaluating and appreciating boxed antique holiday correspondence. These enclosures serve as more than mere protective vessels; they are integral artifacts providing vital information about the origins, authenticity, and historical context of the cards contained within. Preservation significantly elevates the desirability and valuation of the entire collection. A box of holiday greetings from the 1950s, bearing the manufacturer’s logo and original price sticker, offers verifiable evidence of its production and distribution era. Such details are invaluable for authentication and establishing provenance.

The design and construction of the containers further reflect the aesthetic sensibilities and material technology of their time. The containers from the early 20th century featured elaborate graphics, embossing, and paper stock that are valuable to authentication of a true vintage item. The box itself becomes a historical document. Furthermore, the packaging often contains supplementary information such as promotional inserts, manufacturer details, and instructions for use, enriching the collector’s understanding of the product’s intended purpose and market positioning. Complete sets with all original components offer a richer narrative and enhanced value.

In summation, original packaging acts as a crucial piece to authenticate and enhance one’s collectible boxed holiday cards, contributing to a more complete and accurate understanding of a particular boxed set. Its inclusion greatly increases value while also providing insights into the culture and manufacturing practices of its historical period.

Frequently Asked Questions

The following section addresses common inquiries regarding the identification, preservation, and valuation of collectible antique festive correspondence. Understanding these aspects is essential for both novice and experienced collectors.

Question 1: How can one determine the approximate age of a boxed collection of vintage festive greetings?

The age can be estimated through careful examination of printing techniques, paper types, postal markings, and design styles. Consulting historical catalogues and online resources can aid in dating pieces based on these characteristics. Identifying the manufacturer and their historical production periods also provides valuable context.

Question 2: What are the primary factors influencing the monetary worth of a collection?

Monetary worth is influenced by several factors, including the rarity of the designs, the condition of the cards and their box, the presence of original packaging inserts, and the historical significance of the subject matter depicted. Pieces attributed to known artists or linked to specific historical events generally command higher prices.

Question 3: What are the best practices for preserving antique festive correspondence to prevent deterioration?

Preservation requires protecting against environmental factors such as direct sunlight, excessive humidity, and extreme temperature fluctuations. Storing the cards in acid-free archival sleeves or boxes is recommended. Handling the cards with clean hands or archival gloves minimizes the risk of damage.

Question 4: Where can one reliably source genuine boxed collections of antique holiday greetings?

Reliable sources include reputable antique dealers, specialized auctions, estate sales, and established online marketplaces. Verifying the seller’s credentials and requesting detailed images and descriptions before making a purchase is advisable.

Question 5: What distinguishes a reproduction from a genuine vintage card?

Reproductions often exhibit differences in paper quality, printing resolution, and color accuracy compared to authentic vintage cards. Examining the card for modern printing marks or anachronistic typography can help identify reproductions. Consulting with experts can also aid in distinguishing reproductions from genuine articles.

Question 6: Are incomplete sets of antique holiday greetings worth collecting?

While complete sets generally command higher prices, incomplete sets can still hold value, particularly if they contain rare or desirable individual cards. The value of an incomplete set depends on the specific cards included and their overall condition.

In summary, the acquisition, preservation, and valuation of antique holiday greetings require a discerning eye and a commitment to research. The information presented in this section serves as a foundation for informed collecting practices.

The subsequent sections explore specific examples of notable festive correspondence and provide guidance on establishing a personal collection.

boxed vintage christmas cards

Collections of antique festive correspondence in their original containers offer a unique lens through which to examine the past. This exploration has elucidated the multifaceted aspects of these artifacts, encompassing authentication, condition, rarity, artistic merit, subject matter, and the crucial role of packaging. Attention to these elements ensures a more informed and appreciative engagement with these historical items.

As tangible links to bygone eras, these curated assortments not only encapsulate the spirit of holiday celebrations but also serve as valuable repositories of cultural and artistic heritage. Continued study and preservation of boxed vintage christmas cards safeguard these testaments to human creativity and societal evolution for future generations.