An electrical component, typically found in older lighting fixtures, consisting of a ceramic or vitreous housing designed to securely hold a light bulb and provide electrical connections. This type of socket is distinguished by its use of a specific material known for its insulating properties and resistance to heat. Examples include sockets found in antique lamps, early electrical installations, and restored lighting projects where maintaining a period-appropriate aesthetic is paramount.

The significance of this component lies in its durability, historical relevance, and aesthetic appeal. Its robust construction contributes to longevity, often outlasting more modern plastic alternatives. From a historical perspective, it represents a specific era in electrical design and manufacturing. Furthermore, its visual character is frequently sought after in restoration projects and design applications that value authenticity and a connection to the past. The insulating qualities of the ceramic or vitreous material provide a level of safety against electrical hazards.

The subsequent sections will delve into the identification, restoration, and safe handling practices associated with these components, providing guidance for those seeking to preserve or repurpose them. Information on compatibility with modern wiring systems and best practices for ensuring electrical safety will also be covered.

Preservation and Use

The following guidelines aim to offer practical advice concerning the handling, preservation, and safe utilization of these electrical components, commonly found in vintage lighting.

Tip 1: Inspection is Paramount: Before attempting any electrical connection, a thorough inspection of the ceramic housing is critical. Examine for cracks, chips, or any other form of damage. A compromised housing may not provide adequate insulation, posing a safety risk.

Tip 2: Verify Compatibility: Ensure the socket is compatible with the intended light bulb. Confirm the voltage and wattage ratings match the bulb being used. Exceeding the socket’s rated capacity can result in overheating and potential failure.

Tip 3: Wiring Integrity: Inspect the wiring connections within the socket. Over time, wiring can become brittle or frayed. Replace any suspect wiring with appropriate gauge wire rated for the intended voltage and amperage.

Tip 4: Secure Mounting: Ensure the socket is securely mounted within the lamp fixture. A loose socket can create strain on the wiring connections and potentially lead to short circuits.

Tip 5: Grounding Considerations: In applications where grounding is required, verify that the lamp fixture and socket are properly grounded according to local electrical codes. This is a critical safety measure to prevent electrical shock.

Tip 6: Professional Consultation: If uncertainty exists regarding the safety or suitability of a component, consult with a qualified electrician. Attempting electrical repairs without proper knowledge and experience can be hazardous.

Tip 7: Gentle Cleaning Methods: To maintain the aesthetic appeal of the ceramic housing, employ gentle cleaning methods. Avoid abrasive cleaners that can damage the surface. A soft cloth and mild detergent are generally sufficient.

Adhering to these guidelines promotes the safe and effective utilization of these components, preserving a piece of electrical history while ensuring continued functionality.

The subsequent sections will explore advanced restoration techniques and considerations for integrating these vintage components into modern electrical systems.

1. Material Composition

The material composition of these components directly impacts their performance, longevity, and safety. The choice of materials in vintage sockets reflects the technological capabilities and regulatory standards of the time, and understanding these aspects is crucial for preservation and restoration.

- Porcelain Formulation

The specific formulation of the porcelain used in these sockets varied depending on the manufacturer and era. Common ingredients include kaolin clay, feldspar, and silica. The proportions of these materials influenced the porcelain’s firing temperature, hardness, and electrical resistance. A well-formulated porcelain provided excellent insulation and heat resistance, critical for safe operation. Examples include variations in color and texture, indicating differing formulations. Variations may also influence durability over time.

- Glaze Application

A glaze is typically applied to the porcelain to create a smooth, non-porous surface. This glaze not only enhances the aesthetic appeal but also further improves the socket’s resistance to moisture and dirt. The type of glaze used, its thickness, and its application process can all affect the socket’s performance. Examples include identifying crazing or cracking in the glaze, indicating potential material degradation. A well-applied glaze ensures longevity and minimal maintenance.

- Metal Components

While the primary insulating material is porcelain, metal components such as the threaded insert, contact points, and screws are integral to the socket’s functionality. These metal parts are typically made of brass or steel, chosen for their conductivity and corrosion resistance. The quality of these metals and the method of their attachment to the porcelain can significantly impact the socket’s lifespan. Examples include corrosion of brass components affecting conductivity or the loosening of screws causing electrical arcing. High-quality metal ensures reliable electrical contact and secure assembly.

- Asbestos Content (Caution)

In some vintage examples, particularly those manufactured before the widespread awareness of its dangers, asbestos may have been incorporated into the socket’s construction, often in the form of a heat-resistant washer or internal component. Asbestos poses a significant health risk if disturbed. Extreme caution must be exercised when handling such sockets. Identification requires expertise, and professional asbestos abatement may be necessary. Safe handling procedures and disposal are paramount to protect against asbestos exposure.

The interplay of these material aspects defines the overall quality and safety of the component. Careful evaluation of these elements is essential when assessing the condition of a vintage socket, ensuring its suitability for continued use or restoration. Prioritizing safety, especially regarding potential asbestos content, is paramount in handling these electrical components. Understanding the intricacies of material composition provides a crucial foundation for responsible preservation efforts.

2. Electrical Rating

The electrical rating, expressed in voltage and wattage, is a critical parameter defining the safe operational limits of a vintage porcelain lamp socket. The rating indicates the maximum electrical load the socket can handle without risk of overheating, insulation failure, or fire. This specification was determined by the manufacturer based on the socket’s design, materials, and intended use. Exceeding the rated wattage causes excessive heat, which can degrade the porcelain, melt wiring insulation, and ultimately lead to electrical hazards. A practical example is a socket rated for 60 watts used with a 100-watt bulb, significantly increasing the risk of failure and potential fire. Conversely, using a bulb with a wattage lower than the maximum rated value is generally safe, though compatibility with voltage remains essential.

Understanding the electrical rating necessitates a careful examination of any markings on the socket itself. These markings, often embossed or stamped into the porcelain, provide vital information about the intended voltage (typically 120V or 240V depending on the region) and maximum wattage. However, the markings may be faded or illegible due to age and wear. In such cases, consulting historical catalogs or electrical engineering resources may provide clues. Furthermore, the physical size and construction of the socket offer some indication of its capacity. Larger sockets with more robust internal components typically have higher wattage ratings. Yet, relying solely on visual assessment is insufficient, and confirmation through documented specifications is ideal.

In summary, the electrical rating dictates the safe and appropriate use of a vintage porcelain lamp socket. Disregarding this rating invites significant electrical risks. While the aesthetic appeal and historical value of these sockets are undeniable, safety considerations must take precedence. Prior to utilizing a vintage socket, a thorough inspection for visible markings and, if possible, confirmation of its original specifications are essential steps in ensuring safe and reliable operation within a modern electrical system. If there is any doubt regarding the integrity or rating of the socket, a qualified electrician should be consulted.

3. Thread Compatibility

Thread compatibility, in the context of a ceramic lamp component, refers to the standardized dimensions of the threaded portion designed to accept a light bulb. This standardization ensures interchangeability between bulbs and sockets, facilitating ease of use and maintenance. The threads, typically adhering to Edison Screw (ES) or Bayonet Cap (BC) standards, are critical for both mechanical retention and electrical contact. Mismatched threads can lead to insecure bulb seating, causing flickering, arcing, or complete failure. For instance, attempting to install an E26 bulb (North American standard) into an E27 socket (European standard) may appear to fit initially, but the subtle dimensional difference compromises contact and can cause overheating. The functionality of the socket is entirely dependent on this precise mechanical and electrical interface; without it, the component is rendered useless.

The implications of incorrect thread matching extend beyond mere inconvenience. Incompatible threads can damage both the bulb and the socket, necessitating costly repairs or replacements. Moreover, a poorly seated bulb can create a fire hazard due to increased resistance and localized heating. Thread integrity is also vital when restoring vintage lighting fixtures. Maintaining original thread standards is essential for preserving the historical authenticity and functionality of the lamp. Adapters are available to bridge certain thread discrepancies, but their use should be approached cautiously, ensuring that the adapter itself meets all safety standards and does not introduce additional points of failure. Restoration projects should aim for like-for-like replacements whenever feasible to maintain the original design intent and safety margins.

Ultimately, the correct thread compatibility guarantees reliable electrical contact, secure bulb retention, and safe operation. Recognizing thread types and understanding their interchangeability, or lack thereof, is paramount when dealing with these electrical components. Challenges arise in identifying obscure or obsolete thread types, particularly in very old fixtures. Careful measurement and comparison to standardized thread charts are necessary. In situations where identification proves difficult, consulting with a lighting specialist or antique lamp restorer is advisable. Ensuring thread integrity contributes directly to the broader goal of safe and effective lighting, linking historical preservation with modern electrical safety practices.

4. Insulation Integrity

Insulation integrity is paramount in electrical components, particularly in the context of a “vintage porcelain lamp socket,” as it directly mitigates the risk of electrical shock and fire hazards. The insulating properties of the porcelain and any supplementary materials are critical for safe operation, especially considering the age and potential degradation of these components.

- Porcelain Composition and Microfractures

The composition of the porcelain itself dictates its insulating capability. Over time, microfractures may develop due to thermal stress, physical impacts, or material aging. These fractures can compromise the insulating barrier, creating paths for electrical current to leak or arc to grounded surfaces. Examination under magnification can reveal these subtle defects, which are often invisible to the naked eye. Sockets exhibiting such damage should be considered unsafe for continued use.

- Glaze Condition and Moisture Ingress

The glaze applied to the porcelain serves as an additional layer of insulation and prevents moisture from penetrating the porous ceramic material. Cracks, chips, or complete loss of the glaze expose the underlying porcelain to environmental factors, reducing its dielectric strength. Moisture absorption significantly lowers the insulating properties, creating a potential path for current leakage. A continuous, intact glaze is essential for maintaining the socket’s insulating capabilities. Evidence of water stains or mineral deposits suggests compromised glaze integrity.

- Wiring Insulation and Degradation

The condition of the wiring connected to the socket is equally important. Vintage wiring often utilizes rubber or cloth insulation, which can become brittle, cracked, or frayed with age. Exposed conductors create a direct shock hazard and increase the risk of short circuits. Replacing deteriorated wiring with modern, appropriately rated insulation is crucial for ensuring electrical safety. Note areas where the wiring enters the socket, as these points are particularly susceptible to wear and tear.

- Contact Point Integrity and Carbon Tracking

The internal contact points within the socket, where the bulb connects, must be free of corrosion and maintain adequate spacing to prevent arcing. Over time, carbon tracking may occur, forming conductive pathways across the insulating surface. Carbon tracking is often visible as dark, branching patterns on the porcelain. Such tracking significantly reduces the insulation resistance and poses a serious fire risk. Cleaning and, if necessary, replacing corroded contacts are essential for maintaining insulation integrity.

The multifaceted nature of insulation integrity underscores its importance in the safe operation of a “vintage porcelain lamp socket”. Addressing each potential failure point through careful inspection, appropriate maintenance, and necessary replacements is essential for mitigating electrical risks and preserving the functionality of these historical components. Replacing the entire socket is the most reliable method of ensuring long term safety.

5. Historical Authenticity

In the realm of vintage lighting, the concept of historical authenticity holds significant value. This principle dictates the preservation of original components, materials, and manufacturing techniques, seeking to maintain the integrity of the object as a representation of its specific era. For the “vintage porcelain lamp socket,” historical authenticity becomes a critical consideration in restoration, preservation, and adaptive reuse.

- Material Sourcing and Reproduction

Achieving historical authenticity often involves sourcing materials that accurately reflect those used in the original manufacturing process. This can be challenging, as certain materials, like specific formulations of porcelain or wiring insulation, may no longer be readily available or meet modern safety standards. Reproduction components, created using historical research and techniques, may be employed to maintain the object’s original aesthetic and functional properties. However, the use of reproduction parts must be carefully documented to avoid misrepresentation of the item’s age and origin. For example, a socket may be meticulously rewired with cloth-covered wire to maintain its original appearance, but this should be clearly noted in any documentation or description.

- Manufacturing Marks and Identification

Original “vintage porcelain lamp socket” often bear manufacturing marks, logos, or patent numbers that provide valuable information about their origin and date of production. These markings serve as key identifiers for collectors and restorers, allowing them to accurately classify and date the component. The presence of such marks can significantly enhance the historical value and desirability of the socket. Documenting and preserving these markings is an essential aspect of maintaining historical authenticity. A faded logo from a specific manufacturer, for example, may indicate the socket’s production date and original intended use.

- Patina and Wear Patterns

The natural patina and wear patterns that develop on a vintage object over time contribute to its historical character. Cleaning and restoring a “vintage porcelain lamp socket” requires careful consideration of these elements. While removing excessive dirt and corrosion is necessary for functionality and safety, preserving the subtle signs of age is crucial for maintaining historical authenticity. Over-cleaning or aggressive restoration techniques can erase these valuable indicators of the object’s past. The light discoloration and minor surface imperfections accumulated over decades, for instance, can tell a story of the socket’s usage and environment.

- Conformity to Period Electrical Codes

Restoring a “vintage porcelain lamp socket” for practical use requires balancing historical accuracy with modern safety standards. Adhering to the electrical codes and practices of the socket’s original period is not always feasible or safe in contemporary electrical systems. Modifications to wiring, grounding, or bulb compatibility may be necessary to ensure safe operation. However, these modifications should be implemented in a manner that minimizes disruption to the socket’s original appearance and construction. The key is to enhance safety without compromising the object’s historical integrity. Installing a modern grounding wire while preserving the original wiring configuration exemplifies this balance.

The pursuit of historical authenticity in the context of “vintage porcelain lamp socket” involves navigating a complex interplay of material science, historical research, and preservation ethics. Each decision, from sourcing replacement parts to cleaning original surfaces, must be carefully considered to ensure that the object’s historical value is respected and maintained. Balancing this dedication to authenticity with the practical requirements of safe and functional use requires expertise, sensitivity, and a deep appreciation for the history embodied within these humble electrical components.

Frequently Asked Questions

The following questions address common concerns and provide informative answers regarding the characteristics, safety, and restoration of these vintage electrical components.

Question 1: How can one determine the age of a vintage porcelain lamp socket?

Dating these sockets often relies on identifying manufacturing marks, patent numbers, or logos embossed on the porcelain. These markings can be cross-referenced with historical catalogs and manufacturer records to ascertain the approximate production period. The style of the socket and the materials used in its construction also offer clues.

Question 2: What are the primary safety concerns associated with using vintage porcelain lamp sockets?

Deteriorated insulation, cracked porcelain, and corroded contacts pose the greatest safety risks. The original wiring may be brittle or damaged, and the socket itself may not be grounded. Additionally, some older sockets may contain asbestos. A thorough inspection and professional evaluation are essential before utilizing a vintage socket.

Question 3: Is it possible to safely rewire a vintage porcelain lamp socket for modern use?

Rewiring is possible, but should only be undertaken by a qualified electrician. The existing wiring must be carefully removed, and new, appropriately rated wiring installed. The socket’s porcelain housing must be in good condition, free of cracks or chips, to ensure proper insulation. Grounding is crucial in modern electrical systems.

Question 4: What is the recommended method for cleaning a vintage porcelain lamp socket?

Gentle cleaning with a soft cloth and mild detergent is advised. Abrasive cleaners can damage the porcelain and any existing markings. Ensure the socket is completely dry before reconnecting it to an electrical circuit. Avoid immersing the socket in water.

Question 5: Can a vintage porcelain lamp socket be used with modern LED bulbs?

Theoretically, yes, provided the voltage and wattage ratings of the socket are compatible with the LED bulb. However, careful consideration must be given to heat dissipation. LED bulbs generate less heat than incandescent bulbs, but the vintage socket may not be designed for the specific heat characteristics of LEDs.

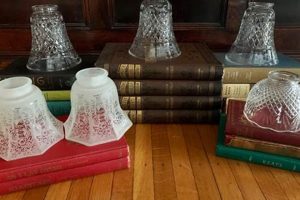

Question 6: Where can replacement parts for vintage porcelain lamp sockets be sourced?

Replacement parts may be found at antique lighting stores, online retailers specializing in vintage electrical components, or from salvage yards. When sourcing replacements, ensure they are compatible with the original socket in terms of size, thread type, and electrical rating. Prioritize parts that meet current safety standards.

These FAQs underscore the need for caution and informed decision-making when working with vintage electrical components. Safety should always be the paramount concern.

The subsequent section will delve into case studies of successful vintage lighting restoration projects.

Conclusion

This exploration of the “vintage porcelain lamp socket” has underscored its multifaceted nature, encompassing historical significance, material science, and electrical safety. The examination has revealed that these components, while aesthetically appealing and historically relevant, demand careful assessment and responsible handling. Factors such as material composition, electrical rating, thread compatibility, and insulation integrity must be meticulously evaluated to ensure safe and effective utilization.

The information presented herein serves as a foundation for informed decision-making regarding the preservation, restoration, and integration of these vintage electrical components. It is incumbent upon those engaging with “vintage porcelain lamp socket” to prioritize safety and historical accuracy, adhering to best practices and seeking expert consultation when necessary. The proper stewardship of these objects not only preserves a tangible link to the past but also safeguards against potential electrical hazards. The longevity and functionality of a “vintage porcelain lamp socket” relies heavily on proper installation and maintenance.