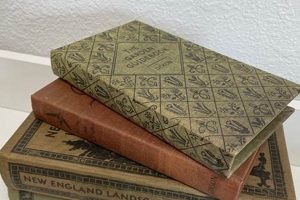

Receptacles of a bygone era, these kitchen containers, often constructed from tinplate or enameled steel, were designed to store baked goods. Their materiality, typically a form of treated ferrous alloy, ensured durability and offered protection against pests and environmental factors that could compromise the contents.

The utilization of metallic materials in these household objects provided a functional solution for preserving freshness before the advent of modern refrigeration and plastic storage. Their prevalence highlights a period when practicality and longevity were prioritized in domestic tools, reflecting a resourceful approach to food preservation.

This historical context sets the stage for a deeper exploration into the specific types of metal used, the design evolution of these containers, and their current status as collectibles and objects of historical significance.

Tips for Identifying and Preserving Antique Kitchen Containers

This section provides guidance on discerning authentic examples and maintaining their condition. Proper identification and preservation will ensure the longevity and value of these items.

Tip 1: Material Examination: Analyze the metal composition. Authentic examples often exhibit characteristics of tinplate, enameled steel, or, in rarer instances, early forms of stainless steel. Note any signs of rust, corrosion, or degradation.

Tip 2: Construction Techniques: Investigate the manufacturing methods. Riveted joints, folded seams, and hand-painted details are indicative of older production techniques. Modern reproductions typically employ welding or stamped construction.

Tip 3: Paint and Graphics Analysis: Evaluate the paint. Original paint may show signs of age, such as crazing or wear. Examine the graphics for printing techniques consistent with the purported era of manufacture, such as lithography or stenciling.

Tip 4: Internal Condition Assessment: Inspect the interior for remnants of food storage or cleaning agents. The presence of staining or corrosion can influence the overall value but may also provide insights into its usage history.

Tip 5: Rust Prevention: Address rust immediately. Gentle cleaning with appropriate solvents and the application of a rust inhibitor are crucial for halting further deterioration.

Tip 6: Gentle Cleaning Practices: Avoid abrasive cleaning agents or harsh chemicals, as they can damage the finish or paint. Opt for mild soap and water, and use soft cloths to prevent scratching.

Tip 7: Controlled Storage Environment: Maintain a stable storage environment with low humidity. Fluctuations in temperature and humidity can accelerate corrosion and degradation of the metal.

Applying these tips allows for informed decisions regarding acquisition, restoration, and long-term preservation. Recognizing the subtle characteristics of these containers is essential for both collectors and those interested in preserving historical artifacts.

The subsequent sections will delve into the design variations, decorative motifs, and the factors that contribute to the collectible value of these historical pieces.

1. Material Composition

The choice of materials is paramount to understanding the functionality, longevity, and historical context of these storage containers. The metal utilized directly influenced its resistance to corrosion, its ability to maintain stable internal conditions, and its aesthetic properties.

- Tinplate as a Primary Material

Tinplate, a thin sheet of steel coated with tin, was frequently used due to its affordability and resistance to rust compared to bare steel. However, the tin coating could be susceptible to scratches and wear, exposing the underlying steel to potential corrosion over time. Examples include early 20th-century containers often found with lithographed designs directly printed onto the tinplate.

- Enameled Steel for Enhanced Durability

Enameled steel offered improved durability and resistance to corrosion. The enamel coating, a layer of glass fused to the steel surface at high temperatures, provided a hard, non-porous barrier. This made the container easier to clean and less prone to rust. Common examples feature vibrant colors and decorative motifs, as the enamel provided an excellent surface for decoration.

- Iron’s Presence and its Implications

While less common as the primary material for the entire container due to its susceptibility to rust, iron components were often incorporated into hinges, latches, or reinforcement structures. The presence of iron elements necessitates careful inspection for rust damage and appropriate conservation measures to prevent further degradation. These are often found on earlier, more utilitarian designs.

- Variations in Steel Gauge

The thickness, or gauge, of the steel employed significantly impacted the container’s structural integrity. Thicker gauge steel provided greater resistance to dents and deformation, contributing to the overall longevity of the item. Examining the gauge can offer insights into the intended usage and quality of the original manufacturing process. Often, higher-end models featured thicker gauge steel.

The selection of materials for these containers was driven by a combination of cost, availability, and the desired level of protection for the stored goods. By understanding the material composition, one can better assess the condition, authenticity, and appropriate conservation methods for any of this kind of kitchen object.

2. Construction Techniques

The methods employed in assembling these containers reflect the technological capabilities and manufacturing priorities of their respective eras. Examination of these techniques provides valuable insights into the age, origin, and overall quality of the item.

- Seam Construction Methods

Seams, where separate pieces of metal are joined, exhibit varied techniques. Early examples frequently feature lapped and riveted seams, offering durability but requiring manual labor. Later, folded or lock-seamed construction, often machine-produced, became prevalent, increasing production speed but sometimes sacrificing robustness. The type of seam is a strong indicator of age and manufacturing process.

- Lid Attachment Mechanisms

Lid attachment evolved over time. Hinged lids, secured with riveted or soldered hinges, were common, allowing for easy access. Detachable lids, sometimes with friction-fit designs or simple latches, offered alternative closure methods. The complexity and material quality of the lid attachment directly influenced the container’s longevity and resistance to damage.

- Base and Foot Design

The base or foot design influences stability and protects the container from direct contact with surfaces. Some models feature simple, flat bases, while others incorporate raised feet or pedestal designs. The presence of raised feet helps prevent moisture buildup and reduces the risk of corrosion. The type of base is often indicative of the intended setting and usage.

- Handle and Hardware Integration

Handles, latches, and decorative hardware elements were integrated using various techniques. Riveting, soldering, and spot welding were common methods. The quality of the hardware and its attachment points directly impacts the container’s usability and aesthetic appeal. Original hardware in good condition enhances its collectible value.

These construction details, when considered in conjunction with material composition and design characteristics, provide a comprehensive understanding of the historical manufacturing processes and the inherent value of these items. Careful examination of these elements is crucial for authenticating, dating, and properly preserving these containers.

3. Paint Condition

The paint finish on containers is a crucial indicator of its history, authenticity, and value. Deterioration occurs due to environmental factors, usage, and storage conditions. Exposure to sunlight, temperature fluctuations, and humidity can cause fading, cracking, and blistering. Abrasive cleaning methods and physical impact can result in scratches, chipping, and complete removal of the original paint. The extent and type of paint damage directly influence the collectible value and historical significance of the piece. For instance, a model with largely intact original paint, even with some wear, commands a higher price than a similar piece with a poorly executed repaint.

Furthermore, the paint condition is often indicative of the overall care and preservation efforts undertaken throughout the container’s history. A unit exhibiting minimal paint loss and damage suggests it was likely stored in a controlled environment and handled with care. Conversely, substantial paint degradation often signifies exposure to harsh conditions or neglect. Original paint, even in a deteriorated state, provides insights into the original color schemes, decorative motifs, and manufacturing techniques employed. Examination under magnification can reveal layering, brush strokes, or printing methods that authenticate the piece and distinguish it from reproductions. The presence of lead-based paint, common in older examples, requires caution during handling and restoration.

In summary, paint condition is a multifaceted aspect. Its assessment involves considering the type and extent of damage, its relationship to the overall history and preservation of the object, and its implications for value and restoration. A comprehensive understanding of paint condition enables informed decisions regarding acquisition, conservation, and long-term care, ensuring the preservation of its inherent qualities for future generations.

4. Rarity Factors

The scarcity of certain examples significantly elevates their value within the collector market. Several key factors contribute to the designation of rarity, influencing demand and market prices.

- Limited Production Runs

Containers manufactured in small quantities, often due to specialized designs or short-lived manufacturing partnerships, are inherently rarer. Examples include those produced during wartime material restrictions or promotional runs for specific brands. The scarcity of these units increases their desirability among collectors.

- Unique Decorative Elements

Models featuring atypical or experimental decoration schemes, such as hand-painted artwork or unusual lithographic prints, command higher premiums. These deviations from standard production designs often result from limited-edition releases or custom orders. Such distinctive embellishments render each container a unique artifact.

- Manufacturer’s Markings and History

Containers produced by lesser-known or defunct manufacturers often possess significant rarity. The historical documentation associated with these manufacturers, or the lack thereof, contributes to their mystique and collectible appeal. Identifying and verifying these markings requires specialized knowledge and research.

- Exceptional Condition for Age

Containers that have survived in remarkably well-preserved condition, exhibiting minimal wear or damage despite their age, are considered rare. The survival of original paint, intact hardware, and absence of significant corrosion are highly valued attributes. The degree of preservation is a critical determinant of rarity.

These facets of rarity, when considered collectively, determine the desirability and market value of a these kitchen containers. The intersection of limited production, distinctive design, historical significance, and exceptional condition creates a compelling narrative for collectors and enthusiasts.

5. Storage History

The environmental and usage conditions endured throughout its lifespan significantly impact the present state and historical narrative of any metal kitchen container. The story of its storage is etched into the material, finish, and overall condition, providing crucial insights into its authenticity and value.

- Environmental Exposure Effects

Prolonged exposure to humidity, temperature fluctuations, or direct sunlight accelerates corrosion, paint degradation, and material fatigue. The presence of extensive rust, faded paint, or warped metal often indicates storage in uncontrolled environments such as damp basements, uninsulated garages, or direct sunlight. These environmental factors leave indelible marks that inform about the container’s past.

- Evidence of Pests and Infestation

The presence of rodent droppings, insect remains, or gnaw marks suggests exposure to unsanitary storage conditions. These infestations can cause physical damage to the metal and paint, and may also introduce contaminants that compromise the structural integrity. The detection of such evidence requires careful cleaning and disinfection protocols to ensure safe handling and preservation.

- Contents and Residual Odors

The type of food items previously stored can leave lasting traces in the form of stains, residues, or persistent odors. The presence of oily residues suggests the storage of baked goods or other high-fat content foods, while musty or moldy odors indicate potential moisture damage. These remnants provide clues about its intended use and storage habits.

- Cleaning and Maintenance Practices

Evidence of abrasive cleaning methods, improper storage techniques, or the use of harsh chemicals can manifest as scratches, paint loss, or discoloration. Conversely, careful cleaning and maintenance practices may result in minimal wear and damage, preserving the container’s original condition. The presence of these traces reveals the care given to it throughout its history.

These facets of storage history contribute to a comprehensive understanding of the container’s past. Examining these clues offers insights into its authenticity, condition, and value. This knowledge informs decisions regarding preservation, restoration, and responsible ownership, ensuring its legacy endures.

6. Rust Prevention

The inherent susceptibility of ferrous alloys to oxidation presents a significant challenge in the preservation of vintage metal bread boxes. The interaction between iron (a primary component of steel and tinplate) and environmental elements, particularly moisture and oxygen, initiates the corrosive process known as rust. This process weakens the structural integrity of the metal, compromising both the aesthetic appeal and the functional capacity of the container. For example, prolonged exposure to humid conditions in a kitchen environment can lead to the formation of surface rust, which, if left untreated, progresses to deeper pitting and eventual disintegration of the metal.

Effective rust prevention strategies are crucial to mitigating these detrimental effects. Passive methods involve creating a barrier between the metal and the environment. This can be achieved through the application of protective coatings such as waxes, oils, or specialized metal sealants. Active methods, on the other hand, involve the removal of existing rust and the subsequent application of rust inhibitors. The choice of method depends on the extent of corrosion and the type of metal involved. For instance, electrolysis can be employed to remove heavy rust deposits, followed by the application of a phosphoric acid solution to convert remaining rust into a stable, protective layer.

The long-term preservation of these historical artifacts hinges on a proactive approach to rust management. Regular inspection for signs of corrosion, prompt treatment of any emerging rust spots, and the maintenance of a controlled storage environment are essential. Understanding the underlying chemical processes and implementing appropriate prevention techniques ensures the longevity and value of vintage bread boxes, allowing future generations to appreciate these tangible links to the past.

Frequently Asked Questions

This section addresses common inquiries regarding the identification, preservation, and valuation of these historical kitchen containers, offering insights for collectors and enthusiasts alike.

Question 1: How can the authenticity of a metal bread box be verified?

Answer: Authentication involves examining construction techniques (riveted seams vs. welding), material composition (tinplate, enameled steel), paint characteristics (original crazing, printing methods), and manufacturer’s markings. Comparison with known examples and consultation with experts are recommended.

Question 2: What are the primary causes of rust on such containers, and how can it be prevented?

Answer: Rust results from exposure to moisture and oxygen. Prevention strategies include maintaining a dry storage environment, applying protective coatings (waxes, oils), and promptly addressing any signs of corrosion with rust inhibitors.

Question 3: How should the surface of an antique model be cleaned without causing damage?

Answer: Gentle cleaning is crucial. Avoid abrasive cleaners or harsh chemicals. Use mild soap and water with soft cloths. Test cleaning solutions on an inconspicuous area first to ensure compatibility with the paint and metal.

Question 4: What factors contribute to its collectible value?

Answer: Collectible value is influenced by rarity (limited production runs, unique designs), condition (original paint, minimal rust), manufacturer’s history, and historical significance. Provenance, if known, can further enhance value.

Question 5: Is it safe to store food in an old metal bread box?

Answer: While visually appealing, using an antique for food storage is generally discouraged. The presence of lead-based paint (common in older models) and potential rust contamination pose health risks. It’s best reserved for decorative or display purposes.

Question 6: How can the age of an item be estimated?

Answer: Estimating age requires considering manufacturing techniques, design styles, and historical context. Researching manufacturer’s histories, consulting historical catalogs, and comparing the container to dated examples can provide reasonable estimations.

Understanding these key aspects aids in the responsible acquisition, preservation, and appreciation of these historical artifacts.

The subsequent sections will explore specific restoration techniques and considerations for conserving these valuable pieces of kitchen history.

Conclusion

The preceding exploration has illuminated the multifaceted nature of containers constructed from ferrous alloys, emphasizing material composition, construction techniques, paint condition, rarity factors, storage history, and rust prevention. Understanding these elements is critical for accurate identification, responsible preservation, and informed valuation within the collector market. The legacy of these utilitarian objects lies not merely in their metallic form, but in their reflection of past domestic practices and manufacturing capabilities.

Continued research and careful stewardship of these historical artifacts will ensure their survival as tangible representations of a bygone era. Recognizing the significance of “vintage bread box metal” extends beyond mere collecting; it necessitates a commitment to preserving material culture and understanding the evolution of everyday objects. Further investigation into manufacturing processes, design influences, and social contexts will undoubtedly enrich our appreciation of these relics of the past.