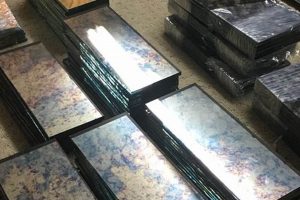

Panels of this type, originally crafted for use in low-lying furniture designed for the central living space, offer a clear, protective surface. These surfaces, often found on pieces dating from the mid-20th century or earlier, vary in thickness, edge treatment, and overall dimensions depending on the table’s design and manufacturer. Examples might include tempered sheets with beveled edges or simple, untempered panes with a flat, polished perimeter.

The significance of these components lies in their preservation of the furniture’s surface and enhancement of its aesthetic appeal. Their historical relevance is tied to evolving design trends and manufacturing processes within the furniture industry. These surfaces provide a barrier against spills, scratches, and other forms of damage, thereby extending the lifespan of the underlying table. Furthermore, its reflective properties contribute to the ambiance of the room.

The subsequent sections will address methods for identifying age and origin, sourcing replacements, and providing proper care and maintenance to ensure longevity. Attention will also be given to the impact of glass characteristics on the overall value and collectibility of related furniture pieces.

Preservation Strategies for Surfaces on Antique Tables

The following recommendations are designed to assist in maintaining the integrity and appearance of surfaces found on period furniture.

Tip 1: Verify Authenticity Prior to Restoration. Before undertaking any repairs or cleaning, ascertain the age and originality of the surface. Examination of manufacturing marks, surface imperfections, and overall condition can provide clues to its provenance. Consult with a qualified appraiser if necessary.

Tip 2: Employ Gentle Cleaning Agents. Avoid abrasive cleaners or harsh chemicals. Instead, use a mild soap solution and a soft, lint-free cloth. Ammonia-based products can degrade certain types of material over time.

Tip 3: Use Appropriate Support. If the panel is loose or unsupported, provide adequate cushioning or bracing to prevent breakage. Consider custom-cut foam padding or non-acidic archival materials.

Tip 4: Document Condition Before Alteration. Prior to any cleaning or repair work, take detailed photographs to document the existing state. This provides a reference point and protects against liability in case of damage.

Tip 5: Implement UV Protection Measures. Prolonged exposure to ultraviolet light can cause fading and discoloration. Use UV-filtering window film or keep the table out of direct sunlight.

Tip 6: Address Minor Scratches Promptly. Small surface abrasions can often be minimized with specialized polishing compounds designed for use on this material. Test the compound on an inconspicuous area first.

Tip 7: Ensure Adequate Ventilation. Condensation can lead to etching and damage. Maintain proper airflow around the furniture to minimize moisture buildup.

Adherence to these guidelines will contribute significantly to the conservation of these surfaces, preserving their historical value and aesthetic qualities for years to come.

The concluding section will discuss strategies for safe storage and transport of furniture with these fragile components.

1. Material Composition

The material constituents of panels in older coffee tables are central to both authentication and conservation. Prior to the mid-20th century, formulations differed considerably from modern soda-lime formulations. Lead content, often incorporated to enhance clarity and workability, is a notable characteristic of earlier production. This composition impacts both the weight and refractive index of the resulting product. For example, examination of an Art Deco coffee table element might reveal a significantly higher lead concentration compared to those found in mid-century modern pieces, leading to specific handling and disposal concerns. This inherent composition dictates appropriate cleaning methods, as certain chemicals can react adversely with specific components, leading to irreversible damage such as clouding or etching.

The presence or absence of certain elements can also serve as an indicator of manufacturing origin. Specific European manufacturers, for instance, were known for utilizing particular silica sources, resulting in unique trace element profiles. Spectrographic analysis, while often impractical for routine assessment, can provide definitive identification of the glass’s origin based on its elemental composition. Understanding the composition further allows for informed matching of replacement glass when complete conservation is not feasible. Opting for contemporary material that closely mirrors the original’s refractive index and color characteristics is crucial for maintaining the piece’s visual integrity.

In summation, awareness of the material composition allows a targeted approach to preservation and restoration. The presence of lead, the silica source, and manufacturing additives all influence the long-term stability and aesthetic properties. By understanding the characteristics, it is possible to implement appropriate conservation strategies. Consideration of safety in handling, informed choice of cleaning agents, and informed matching are facilitated through an understanding of its materiality.

2. Edge Treatment

The finishing applied to the perimeter of surfaces in older coffee tables is a critical indicator of age, manufacturing technique, and intended design aesthetic. These treatments, often subtle, provide valuable insights into the piece’s history and construction.

- Beveled Edges

Beveling, involving the angled grinding and polishing of the edge, was frequently employed on higher-end furniture from the Art Deco and earlier periods. The width and angle of the bevel varied depending on the manufacturer and style. A wide, highly polished bevel, for example, suggests a more luxurious piece, while a narrow, less refined bevel may indicate a mass-produced item. The presence of a beveled edge often implies a higher level of craftsmanship and attention to detail. The absence of beveling, conversely, doesn’t necessarily indicate lesser quality but rather a different design philosophy or cost constraint.

- Pencil-Rounded Edges

This treatment, characterized by a gently rounded edge resembling a pencil’s profile, was commonly used during the mid-century modern era. This offers a balance of safety and aesthetics. The rounded edge softens the profile while minimizing the risk of chipping or sharp edges. The consistency and smoothness of a pencil-rounded edge reflect the quality of the grinding and polishing process. Irregularities or imperfections may indicate hand-finishing or wear over time. This edge profile is particularly suited to styles emphasizing simplicity and functionality.

- Flat Polished Edges

A flat polished edge is achieved by grinding the edge square and then polishing it to a smooth, reflective surface. This method offers a clean, minimalist aesthetic. This is often found on pieces designed for contemporary settings. The precision and evenness of the polished surface are indicators of manufacturing quality. Scratches or chips along the edge are common signs of wear and tear. However, significant damage may compromise the structural integrity of the surface. This is the least expensive edge treatment; typically.

- Seamed Edges

Seaming, also known as a ground edge, involves lightly grinding the sharp edges to reduce the risk of cuts. The seamed edge offers a functional solution for safety without the aesthetic refinement of polishing or beveling. In particular, this finish is a sign of furniture made for safety. Seamed edges are common in mass production. This treatment is often an indicator of cost-consciousness or a focus on practicality over visual appeal. However, even within seamed edges, variations in the quality of grinding can be observed, with smoother seams indicating a higher degree of manufacturing care.

These different perimeter treatments provide telltale clues about the vintage coffee table glass’s origin and intended purpose. Recognizing these nuances is key to ensuring authentic replacements or repairs that align with the piece’s original design and value.

3. Thickness Variation

The dimension of panes found in older coffee tables, while seemingly uniform, often exhibits measurable variation. These deviations are not necessarily defects but rather artifacts of the manufacturing processes prevalent during specific historical periods. Understanding the causes and implications of thickness fluctuation aids in authenticating the age and assessing the structural integrity of these surfaces.

- Manufacturing Technique

Hand-blown and early machine-rolled methods inherently produced greater thickness inconsistencies than modern float processes. Hand-blown panes, in particular, demonstrate significant irregularities, as the expansion and flattening were manually controlled. Early machine-rolled material, while more consistent than hand-blown, still exhibited localized thickness changes due to uneven pressure during the rolling process. Examination of this material reveals subtle undulations and variations discernible through precise micrometry.

- Edge Treatment Influence

The finishing applied to the perimeter can influence apparent dimension. Beveled edges, for example, reduce thickness near the edge, creating an optical illusion of greater variation. Similarly, pencil-rounded edges slightly reduce the overall dimension compared to flat-polished edges. Accurate measurement necessitates accounting for the edge treatment to avoid misinterpreting the results.

- Stress Distribution

Uneven dimension can introduce internal stresses, particularly in tempered material. Localized thick spots may experience higher stress concentrations during the tempering process, increasing the risk of fracture under load. The presence of significant variation necessitates careful assessment of the structural integrity, particularly if the element is subjected to heavy use. Polarized light can sometimes reveal stress patterns related to dimension irregularities.

- Authenticity Indicator

The degree of dimensional consistency can serve as a valuable indicator of age and manufacturing origin. Highly consistent dimension suggests modern float processing, while significant irregularity points to older, less precise techniques. The presence of subtle variation is often a positive sign of authenticity, while perfectly uniform dimension may raise questions about the element’s age and origin. Consulting with a qualified appraiser may be necessary to determine the appropriate range of acceptable irregularity for a specific period and style.

These facets demonstrate the multifaceted relationship between dimension and “vintage coffee table glass.” Precise measurement, consideration of manufacturing processes, and assessment of stress distribution provide essential tools for authentication and preservation. Recognition of acceptable variation ranges contributes to informed restoration and replacement decisions, ensuring the long-term integrity and aesthetic value of related furniture pieces.

4. Surface Imperfections

Surface anomalies, encompassing scratches, bubbles, inclusions, and haze, are intrinsic components of “vintage coffee table glass,” directly reflecting manufacturing methodologies and subsequent wear. These imperfections, rather than detracting from value, often serve as authentication markers and indicators of historical context. For instance, pre-1950s panes, crafted through less refined techniques, frequently exhibit trapped air bubbles and subtle surface undulations not present in contemporary equivalents. The presence and type of these imperfections are therefore integral to proper identification.

The nature and extent of surface damage further provide insights into the item’s usage history and environmental exposure. Fine scratches, frequently radiating from a central point, might suggest repeated cleaning with abrasive materials. A milky or iridescent haze, conversely, can indicate prolonged exposure to humidity or chemical agents. While excessive damage can compromise structural integrity and diminish aesthetic appeal, the presence of age-appropriate wear is often considered desirable, imbuing the element with character and attesting to its authenticity. Conservators and collectors frequently prioritize retaining these features where possible, opting for gentle cleaning and preservation over aggressive restoration that might erase historical evidence.

In conclusion, surface imperfections are not simply flaws but essential attributes of “vintage coffee table glass.” Their detailed assessment provides insights into manufacturing processes, usage history, and authenticity. Recognizing the significance of these details is crucial for responsible conservation, accurate appraisal, and the preservation of cultural heritage. Understanding the story behind them allows for the recognition and valuation of the surface anomalies present in any vintage piece of glass. Recognizing these surface imperfections allows for a deeper appreciation.

5. Original Dimensions

The physical measurements of “vintage coffee table glass” constitute a fundamental attribute, directly influencing both its functional suitability and aesthetic harmony within the intended furniture design. Deviation from original dimensions, whether through imprecise manufacturing or subsequent alteration, compromises the integrity of the design. The size, length, width, and thickness determine structural stability, load-bearing capacity, and the overall proportion relative to the table frame. For example, a replacement panel significantly thinner than the original risks breakage under normal use, while an oversized panel may not fit securely within the frame, creating instability. These dimensions are dictated by original design requirements.

Preserving or accurately replicating “original dimensions” is crucial when restoring antique or vintage coffee tables. Discrepancies in size can alter the table’s visual balance and negatively affect its perceived value. Sourcing replacement elements with precise measurements ensures a seamless fit, maintaining the table’s intended aesthetic and functional attributes. For instance, an Art Deco piece typically exhibits specific dimension ratios between the material and the supporting structure; replicating these proportions accurately preserves the intended visual impression. Accurate dimensions are achieved during manufacturing.

In summary, the dimensions are not merely arbitrary figures but critical parameters that define the form, function, and value of “vintage coffee table glass.” Understanding their significance allows for informed conservation practices, accurate appraisals, and the successful restoration of antique and vintage coffee tables. Challenges arise in sourcing perfectly matching replacements due to variations in historical manufacturing standards. However, meticulous measurement and adherence to original specifications are paramount in preserving the authentic character of these pieces.

6. Manufacturing Marks

The presence, absence, and characteristics of manufacturing marks on “vintage coffee table glass” serve as primary indicators of origin, date, and production methods. These marks, whether intentionally applied or incidentally created during the manufacturing process, provide valuable evidence for authentication and provenance research. Their interpretation requires a nuanced understanding of historical manufacturing practices and the identifying conventions employed by various companies.

- Embossed or Etched Trademarks

Many manufacturers of the 20th century and earlier incorporated trademarks directly into the material during the molding or finishing stages. These marks, often appearing as raised lettering or etched symbols, identify the producer and may include additional information such as patent numbers or model designations. For example, the presence of a specific trademark associated with a known glassworks provides strong evidence of the material’s origin and approximate date of manufacture. The absence of a trademark, however, does not automatically indicate inauthenticity, as some manufacturers did not consistently mark their products.

- Pontil Scars

On hand-blown pieces, a pontil scar, a rough or ground area on the underside, marks the point where the glassblower detached the material from the pontil rod. The shape and characteristics of the pontil scar provide insights into the glassblowing techniques employed. Open pontil scars, for instance, are typically associated with earlier production methods, while ground pontil scars indicate a later refinement in the finishing process. The presence of a pontil scar is a strong indicator that the material was hand-blown, distinguishing it from machine-made material.

- Mold Seams

Machine-made material typically exhibits mold seams, faint lines indicating where the separate sections of the mold joined together. The visibility and prominence of mold seams vary depending on the manufacturing process and the quality of the mold. Well-defined mold seams suggest mass production, while faint or nearly invisible seams may indicate a more refined manufacturing process. The pattern and location of mold seams can also provide clues about the shape and complexity of the mold, offering insights into the manufacturing techniques employed.

- Batch Numbers and Date Codes

Some manufacturers incorporated batch numbers or date codes into the material to track production runs and ensure quality control. These marks, often appearing as small, inconspicuous numbers or symbols, provide precise information about the material’s age and manufacturing history. The interpretation of batch numbers and date codes requires access to manufacturer’s records or specialized databases. However, when deciphered, these marks offer invaluable evidence for dating and authenticating material with a high degree of precision.

These forms are not always easily discernible and may require careful examination under magnification. Their presence or absence, in conjunction with other characteristics, provides a valuable framework for assessing the authenticity, age, and provenance of these components. These characteristics are valuable when determining the value.

7. Optical Clarity

Optical clarity, defined as the capacity to transmit light without significant distortion or obstruction, is a principal attribute governing the aesthetic appeal and functional utility of surfaces in antique coffee tables. Reduced visibility through, or increased distortion within, the material diminishes its capacity to showcase objects placed beneath, impacting the furniture’s intended purpose. The manufacturing processes employed during earlier periods often resulted in variations in optical clarity compared to modern standards. Minute imperfections, such as trapped air bubbles, variations in density, or subtle surface undulations, frequently introduced a degree of light scattering and refraction. For example, examination of Art Deco-era elements reveals a slightly “wavy” appearance when viewed at an angle, a characteristic absent from contemporary float material manufactured with significantly improved precision. Loss of optical clarity can reduce value.

The degree to which clarity is retained or diminished over time is further influenced by environmental factors and maintenance practices. Exposure to ultraviolet radiation can induce solarization, causing a gradual yellowing or browning of the material, thereby reducing light transmission. Abrasive cleaning methods introduce microscopic surface scratches, which cumulatively reduce transparency and create a hazy appearance. The selection of appropriate cleaning agents and the implementation of protective measures, such as UV-filtering films, are essential for preserving the optical characteristics of these surfaces. Failure to maintain surface quality affects clarity.

In summary, optical clarity is a critical determinant of value and visual appeal. Manufacturing techniques, environmental exposure, and maintenance practices exert a significant influence. Recognizing the factors that contribute to or detract from transparency enables informed conservation strategies, ensuring the long-term preservation of antique coffee tables and their aesthetic qualities. Assessment of clarity allows for the understanding of history and processes used.

Frequently Asked Questions Regarding Vintage Coffee Table Glass

The following questions address common concerns and misconceptions surrounding the identification, care, and replacement of surfaces found on antique and vintage coffee tables.

Question 1: How can the age of a coffee table surface be determined?

Age determination involves a multi-faceted approach. Examination of manufacturing marks, edge treatments, material composition, and surface imperfections provides clues. Consulting with a qualified appraiser is advisable for accurate dating.

Question 2: What cleaning agents are safe to use on antique components?

Mild soap solutions and soft, lint-free cloths are generally recommended. Avoid abrasive cleaners, ammonia-based products, and harsh chemicals, as these can cause irreversible damage.

Question 3: How should scratches be addressed on the surface?

Minor surface abrasions can often be minimized with specialized polishing compounds designed for material. Test the compound on an inconspicuous area first. Deep scratches may require professional restoration.

Question 4: Where can replacement components be sourced?

Replacements can be sourced from specialty antique shops, salvage yards, or custom fabrication services. Ensure that the replacement matches the original in terms of thickness, composition, and edge treatment.

Question 5: What factors influence the value of a coffee table with this component?

Value is influenced by the overall condition, rarity, provenance, and aesthetic appeal of the table. The integrity and originality of the surface are also significant factors.

Question 6: How can “vintage coffee table glass” be protected from damage during storage?

The surface should be wrapped in protective padding, such as archival paper or bubble wrap. The table should be stored in a climate-controlled environment away from direct sunlight and excessive humidity.

Proper care and informed decision-making are essential for preserving these components, ensuring their longevity and aesthetic value.

The subsequent section will address strategies for safe storage and transport of furniture with such components.

Conclusion

“Vintage coffee table glass,” as explored in this exposition, represents more than a mere surface; it embodies historical context, manufacturing techniques, and aesthetic considerations pertinent to furniture design. This assessment has underscored the importance of understanding its material composition, edge treatment, thickness variations, surface imperfections, original dimensions, manufacturing marks, and optical clarity. These characteristics are critical for authentication, preservation, and valuation.

The diligent application of the principles outlined herein will contribute to the informed care and appreciation of furniture incorporating “vintage coffee table glass.” Continued research and documentation are vital for safeguarding this element of material culture, ensuring its preservation for future generations. The meticulous study of “vintage coffee table glass” serves not only to protect objects of value but also to illuminate the evolution of design and technology.