A specialized piece of equipment designed for the manipulation of thick, sturdy material, this particular type of apparatus from an earlier era facilitated the crafting of durable goods. These machines, often constructed with robust components and powerful motors, were essential tools for cobblers, saddle makers, and other artisans working with heavy-duty fabrics. They represent a significant step in the mechanization of textile production for items requiring exceptional strength and resilience.

The importance of these durable devices lies in their ability to reliably stitch through dense materials that would prove challenging, or even impossible, for standard models. Their construction reflects a commitment to longevity, with many examples still functioning effectively today, a testament to the quality of materials and engineering. Historically, they enabled the mass production of leather goods, contributing to economic growth and changing patterns of consumption in various industries.

Subsequent sections will detail the key features that differentiate these tools, provide guidance on identifying and assessing their condition, and offer insights into their care and maintenance, enabling owners to preserve their functionality and value.

Essential Guidance for Working With a Legacy Leather Stitcher

These suggestions provide fundamental knowledge for those acquiring, maintaining, or utilizing a historical apparatus designed for hide work.

Tip 1: Identification is Paramount: Prior to operation, verify the make and model. Thorough documentation exists for many manufacturers, providing insights into original specifications and operating procedures. This information is critical for sourcing compatible parts and performing proper adjustments.

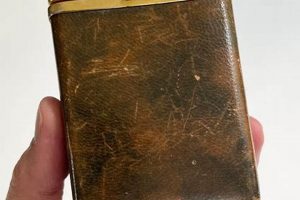

Tip 2: Examine the Physical Condition: Carefully inspect the machine for signs of wear, corrosion, or damage. Pay close attention to the needle bar, feed mechanism, and bobbin winder. Addressing any issues proactively will prevent further complications during use.

Tip 3: Lubrication is Crucial: Establish a regular lubrication schedule using an appropriate oil specifically designed for sewing machinery. Insufficient lubrication contributes to premature wear and can lead to component failure. Consult the manufacturer’s recommendations or a qualified technician for specific guidance.

Tip 4: Tension Adjustments are Critical: Achieving a balanced stitch requires precise tension adjustments on both the needle and bobbin threads. Incorrect tension can result in skipped stitches, thread breakage, or puckering of the material. Test the stitch quality on scrap pieces of leather before beginning any project.

Tip 5: Needle Selection Matters: The correct needle size and type are essential for successful hide work. Select a needle appropriate for the thickness and density of the leather being used. Dull or damaged needles will tear the material and produce subpar results.

Tip 6: Motor Maintenance is Key: Many older machines utilize electric motors. Inspect the motor brushes regularly and replace them as needed. Additionally, ensure the motor is properly grounded to prevent electrical hazards.

Tip 7: Secure Proper Workholding: Due to the robust nature of hide, secure workholding methods are vital. Implement techniques to stabilize the material throughout the stitching operation, fostering precise results and mitigating possible operator injury.

Adhering to these guidelines promotes safe, efficient, and effective utilization. Diligence in these areas protects both the machinery and the user.

The subsequent section delves into troubleshooting common issues and potential repairs associated with these devices.

1. Material Density

Material density is a primary consideration when working with a legacy sewing apparatus designed for heavy-duty textiles. The machine’s capabilities are directly linked to its ability to penetrate and form stitches in materials of varying thickness and resistance. This necessitates a robust design capable of generating the required force.

- Needle Penetration Force

The required force for needle penetration is directly proportional to the density of the leather. Machines engineered for thinner materials lack the power to pierce thick hides. Older models often incorporate a walking foot mechanism to aid in feeding dense materials through the sewing area. Insufficient penetration leads to skipped stitches, broken needles, and damage to the leather.

- Thread Tension Control

Increased material density necessitates precise thread tension adjustments. Thicker hides demand tighter tension to ensure secure stitch formation. Inadequate tension results in loose stitches prone to unraveling. Vintage machines may require more frequent tension adjustments due to wear and tear on tensioning components.

- Feed Mechanism Strength

A powerful feed mechanism is essential for advancing dense leather through the machine. Weak or worn feed dogs struggle to grip the material, leading to uneven stitching and potential jams. Machines featuring a compound feed, which utilizes both a walking foot and feed dogs, are generally better suited for thick hides. The condition of the feed mechanism is a critical factor when evaluating the suitability of a legacy apparatus.

- Motor Power and Gear Reduction

Older units needed more power, therefore the motor is required to generate sufficient torque. Insufficient motor power results in stalled operation, particularly when encountering dense areas of the material. Gear reduction systems amplify the motor’s torque, providing the necessary force to drive the needle and feed mechanism. The motor’s condition and the efficiency of the gear reduction system are significant determinants of the machine’s performance on dense hides.

The interplay between these factors dictates the overall effectiveness of the classic sewing tool when working with dense hides. A thorough understanding of these material properties and their relationship to the mechanical capabilities is essential for achieving successful and durable results. Evaluating these components is crucial when considering purchasing, restoring, or operating such a machine.

2. Stitch Reliability

Stitch reliability is a paramount characteristic of any sewing apparatus, and it holds particular significance for legacy models designed for hide work. The integrity of the stitch directly affects the durability and longevity of the finished product. A compromised stitch can lead to seam failure, rendering the item unusable. For machines originally manufactured decades ago, achieving consistent stitch formation necessitates careful attention to mechanical condition, adjustments, and material compatibility. For example, a saddle crafted using an unreliable stitching process risks disintegration under stress, potentially endangering the rider. Conversely, a well-maintained, properly adjusted classic leather stitcher can produce seams that withstand decades of use.

Several factors contribute to stitch reliability. Thread tension, needle selection, and feed mechanism synchronization are critical. Improper thread tension results in either loose, weak stitches or thread breakage. Using an inappropriate needle damages the leather and prevents proper stitch formation. Misalignment of the feed dogs causes uneven stitching and skipped stitches. Restoring and maintaining proper functionality of these elements in an earlier model requires expertise and access to accurate information regarding original specifications. An instance of improved stitch reliability occurred when a vintage machine owner replaced worn feed dogs, returning the machine to near-original performance and resulting in consistent, strong seams.

In summary, stitch reliability represents a central aspect of legacy hide sewing machinery. While challenges related to wear and component availability may exist, consistent diligence in maintenance and careful adjustments can ensure these tools continue producing high-quality, dependable seams. The practical implications extend beyond mere functionality, impacting product lifespan, safety, and the preservation of traditional craftsmanship.

3. Mechanical Durability

The phrase “mechanical durability” directly relates to the enduring functionality of an older leather sewing apparatus. These machines, often constructed decades ago, were designed for rigorous use, demanding robust components and meticulous engineering. Mechanical durability, in this context, signifies the machine’s capacity to withstand prolonged use and resist wear and tear. For example, machines built with cast iron frames and hardened steel components exhibit significantly greater longevity than those constructed with lighter, less durable materials. The presence or absence of this quality directly influences the machine’s lifespan and its ability to perform reliably over extended periods.

The importance of mechanical durability is amplified by the inherent nature of hide work. Sewing dense materials places substantial stress on the machine’s internal mechanisms. A machine lacking sufficient durability is prone to component failure, requiring frequent repairs and potentially rendering it unusable. Consider a machine used in a small leather goods workshop. If critical parts, such as the feed dogs or needle bar, are manufactured from substandard materials, they will wear down quickly, leading to inconsistent stitch formation and increased downtime. This, in turn, impacts productivity and profitability. Moreover, sourcing replacement parts for older machines can prove challenging and costly, making initial mechanical integrity all the more vital.

In conclusion, mechanical durability is an essential characteristic of classic leather stitching equipment. Its presence ensures long-term functionality, reduces maintenance costs, and contributes to the overall economic viability of using these machines. Evaluating the mechanical condition of a vintage machine prior to purchase is therefore of paramount importance. Prospective buyers must assess the quality of materials used in construction, the extent of wear on critical components, and the availability of replacement parts. Doing so mitigates the risk of acquiring a machine that proves unreliable and costly to maintain.

4. Component Sourcing

Securing replacement components for legacy sewing apparatus designed for hide work constitutes a critical aspect of their continued usability and preservation. The age of these machines means that original parts are often no longer in production, necessitating alternative methods of acquisition to maintain functionality.

- Original Equipment Manufacturer (OEM) Parts

While ideal, obtaining parts directly from the original manufacturer is often impossible due to ceased production or company closure. However, some OEM parts may remain in circulation through specialized dealerships, estate sales, or private collectors. Verification of authenticity and compatibility is crucial to ensure proper fit and function. For instance, a needle plate acquired as OEM may guarantee correct needle alignment and stitch formation, whereas an aftermarket substitute might introduce subtle variations leading to operational issues.

- Aftermarket Parts

A significant portion of replacement components for these apparatuses are now supplied by aftermarket manufacturers. These parts vary widely in quality and adherence to original specifications. Sourcing aftermarket parts requires careful research and scrutiny to ensure compatibility and durability. For example, aftermarket bobbins may exhibit slight dimensional differences compared to the originals, impacting thread tension and winding performance. Positive user reviews and verifiable material specifications are essential considerations.

- Salvaged Components

Dismantling defunct machines provides a source of salvaged components. This practice, while resourceful, necessitates careful inspection and refurbishment of the salvaged parts prior to installation. Salvaged gears, for example, require thorough cleaning, lubrication, and assessment for wear before being reintegrated into a functional machine. The success of using salvaged components hinges on the availability of suitable donor machines and the expertise to assess the condition of reclaimed parts.

- Fabrication and Custom Machining

In cases where neither OEM, aftermarket, nor salvaged components are available, custom fabrication represents a viable alternative. This involves replicating the original part through machining or other manufacturing processes. Custom fabrication demands precise measurements, knowledge of material properties, and access to appropriate manufacturing equipment. For instance, replicating a complex feed dog mechanism may require CAD modeling and CNC machining to achieve the necessary precision and functionality.

The ability to effectively source and utilize replacement components directly impacts the long-term viability of legacy leather stitchers. Whether relying on increasingly scarce OEM parts, carefully vetted aftermarket substitutes, resourceful salvaging, or custom fabrication, securing compatible and durable components is crucial for maintaining the operational integrity and preserving the value of these specialized tools.

5. Operational Safety

Operation of legacy sewing devices designed for hide work necessitates a heightened awareness of safety protocols. These machines, owing to their age and construction, often lack modern safety features integrated into contemporary equipment. A primary concern arises from exposed moving parts such as belts, pulleys, and the needle mechanism itself. Direct contact with these components poses a significant risk of injury. Furthermore, the inherent power of these machines, required to penetrate thick materials, amplifies the potential severity of accidents. For instance, entanglement in a drive belt can result in serious lacerations or fractures, while inadvertent contact with the needle can cause puncture wounds and potential infection. The absence of automatic shut-off mechanisms in many older models increases the importance of operator vigilance. Proper safeguarding practices, including the use of protective guards and strict adherence to operating procedures, are essential to mitigate these risks.

Beyond mechanical hazards, electrical safety constitutes another critical consideration. Many vintage machines feature aging electrical wiring and components, increasing the risk of electrical shock or fire. Regular inspection of wiring, insulation, and grounding is imperative. Replacement of deteriorated wiring with modern, properly rated substitutes is highly recommended. Moreover, operators should ensure the machine is connected to a grounded outlet and avoid using extension cords whenever possible. A failure to address electrical safety concerns can result in severe electrical injuries or property damage. In practical terms, before initiating operation, a thorough inspection of all electrical components by a qualified electrician is advisable. Furthermore, operators should remain vigilant for signs of overheating or unusual electrical activity during operation.

In summary, ensuring operational safety when utilizing a vintage leather stitching device requires a multi-faceted approach. Mitigating mechanical risks necessitates implementing protective measures and adhering to safe operating procedures. Addressing electrical hazards demands careful inspection, maintenance, and potential upgrades to the machine’s wiring and grounding. Recognizing these challenges and implementing appropriate safety measures contributes to preventing accidents, protecting operators, and preserving the functionality of these valuable historical tools. Failure to prioritize safety poses unacceptable risks, potentially leading to injury, equipment damage, or even fatal consequences.

6. Historical Significance

The historical importance of legacy stitching devices designed for working with hides extends beyond their functional utility. These machines represent a tangible link to past manufacturing processes, technological innovation, and evolving industrial practices. Their significance lies in their embodiment of historical ingenuity and their contribution to economic and societal development.

- Technological Advancement and Evolution

These apparatuses exemplify the mechanical ingenuity of their era. The designs often reflect a synthesis of engineering principles aimed at solving specific challenges related to sewing thick and durable materials. Tracing the evolution of these machines provides insights into the progression of manufacturing technology. Early models, for example, frequently featured hand-cranked operation, reflecting the limitations of available power sources. Subsequent iterations incorporated electric motors, enabling increased production speed and efficiency. Examining these advancements reveals the iterative process of technological refinement and adaptation to changing industrial needs.

- Impact on Leather Industries and Craftsmanship

Such machinery profoundly impacted leather-related industries, facilitating mass production of goods that were previously handcrafted. This mechanization contributed to increased availability and affordability of leather products, altering patterns of consumption and trade. Simultaneously, these machines shaped the skills and practices of leatherworkers. Artisans adapted their techniques to incorporate mechanized processes, leading to both increased efficiency and evolving aesthetic styles. Tracing the historical usage of specific models within particular industries, such as shoe manufacturing or saddle making, illuminates their direct influence on production methods and the craftsmanship of leather goods.

- Reflection of Socio-Economic Trends

The production, distribution, and use of these specialized sewing devices mirrored prevailing socio-economic trends. The growth of industrial centers and the rise of mass production created a demand for efficient sewing solutions. Analyzing the geographical distribution of machine manufacturing and the industries in which they were deployed provides insights into regional economic development. Furthermore, the availability and affordability of these machines reflected broader economic conditions and the purchasing power of different social classes. Examining historical advertisements and catalogs reveals the marketing strategies employed to promote these machines and their role in shaping consumer culture.

- Preservation of Traditional Skills and Knowledge

Paradoxically, while enabling mass production, some enthusiasts preserve vintage machines to retain the skill and knowledge needed for the device. By maintaining and restoring vintage machines, there remains an understanding of traditional leatherworking that values quality and preservation.

In essence, legacy leather stitching equipment embodies a confluence of technological, economic, and social forces. Their historical significance extends beyond their mere function as sewing tools; they represent a tangible connection to the past, offering insights into the evolution of manufacturing, the transformation of industries, and the enduring human drive for innovation. Recognizing and preserving these machines contributes to a broader understanding of industrial history and the legacy of craftsmanship.

Frequently Asked Questions

The following addresses common inquiries regarding these specialized tools, offering insights for prospective buyers, current owners, and those interested in their historical significance.

Question 1: What distinguishes a “vintage leather sewing machine” from a standard sewing machine?

Apparatus designed for hide work possesses enhanced capabilities to penetrate and stitch dense materials. Primary distinctions include a more powerful motor, heavy-duty components, and specialized feed mechanisms designed to handle the increased resistance of hides. Standard machines typically lack the robust construction necessary to reliably sew through thick materials.

Question 2: How does age affect the performance and reliability of this type of equipment?

Age can significantly impact performance and reliability. Over time, components experience wear and tear, potentially leading to decreased efficiency and increased maintenance requirements. However, well-maintained machines constructed with high-quality materials can retain their functionality for decades. Pre-purchase inspection is crucial to assess the condition of critical components.

Question 3: Where can replacement parts be found for these discontinued devices?

Sourcing replacement parts can pose a challenge. Potential sources include aftermarket suppliers, specialized dealers in vintage sewing equipment, online marketplaces, and salvaged components from defunct machines. Custom fabrication may also be necessary for certain rare or unavailable parts. Due diligence is required to ensure compatibility and quality.

Question 4: What are the key maintenance requirements for ensuring longevity?

Regular maintenance is essential for maximizing lifespan. Key requirements include consistent lubrication of moving parts, periodic inspection for wear and damage, proper tension adjustments, and timely replacement of worn components. Consulting manufacturer’s documentation or seeking guidance from a qualified technician is recommended.

Question 5: What safety precautions should be observed when operating these machines?

Prioritize safety due to the age of the machine. Users must safeguard exposed moving parts, ensure proper electrical grounding, and adhere to recommended operating procedures. The use of safety glasses and appropriate work attire is advised. Disconnecting the machine from power source during maintenance prevents accidental operation.

Question 6: How does mechanical durability affect the value of an older apparatus?

Mechanical durability is a primary determinant of value. Machines constructed with robust materials and exhibiting minimal wear generally command a higher price. Factors such as the presence of original components, overall condition, and historical provenance also influence valuation. Professional appraisal from a qualified specialist will establish value.

In essence, acquiring, maintaining, or operating classic hide-stitching equipment necessitates careful consideration of its mechanical condition, component availability, and safety requirements. Understanding these factors promotes informed decision-making and maximizes the potential for continued functionality.

The next section will address case studies highlighting successful restorations and innovative uses of vintage leather stitching equipment.

Conclusion

The preceding analysis has elucidated essential facets of “vintage leather sewing machine,” encompassing design characteristics, maintenance considerations, operational safety, and historical context. An understanding of these aspects enables informed decisions regarding acquisition, restoration, and usage. Recognizing the interplay between mechanical durability, component availability, and operator skill is critical for maximizing the lifespan and utility of these specialized tools.

Continued research and preservation efforts are vital to ensure the legacy of these apparatus extends into the future. These machines serve as a testament to industrial innovation and the enduring craftsmanship of leatherworking. A commitment to maintaining their functionality will ensure continued appreciation for the ingenuity and durability embodied within these pieces of mechanical history.