Garments of tanned animal hide, crafted by a specific manufacturer renowned for leather goods, and possessing characteristics indicative of a past era, represent a segment of apparel sought after for its unique qualities. These items often exhibit design elements, materials, and construction techniques representative of previous decades.

The appeal of these older leather outwear pieces lies in their association with particular periods, offering a tangible connection to history and fashion trends of the past. Owning such an item can provide a distinctive style, set apart from contemporary mass-produced alternatives. The craftsmanship found in earlier production runs often surpasses that of modern equivalents, leading to increased durability and aesthetic value. This can evoke feeling of nostalgia or be seen as statement piece.

The subsequent sections will delve into the specific characteristics, care considerations, and avenues for acquiring these aged leather outer layers, while also exploring the factors influencing their value and collectibility.

The acquisition and preservation of legacy leather jackets from this manufacturer necessitate careful evaluation and maintenance to ensure longevity and retain inherent value.

Tip 1: Authenticity Verification: Rigorous examination for indicators of origin is crucial. Inspect labels, hardware, and stitching patterns for consistency with the manufacturer’s historical production standards.

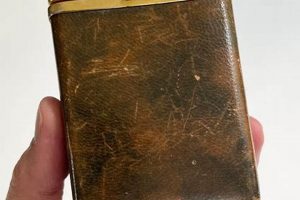

Tip 2: Leather Quality Assessment: Evaluate the condition of the hide. Signs of excessive dryness, cracking, or stiffness denote potential degradation requiring professional restoration.

Tip 3: Hardware Integrity: Assess zippers, buttons, and snaps for functionality and corrosion. Replacement of damaged hardware should utilize components that match the original specifications whenever possible.

Tip 4: Lining Inspection: Examine the lining for tears, stains, or odors. Address any issues promptly to prevent further deterioration and maintain hygiene.

Tip 5: Professional Cleaning: Avoid DIY cleaning methods. Entrust the garment to a leather specialist experienced in handling vintage items to prevent damage.

Tip 6: Proper Storage: Store the garment in a cool, dry environment away from direct sunlight and heat sources. Use a padded hanger to maintain its shape and prevent creasing.

Tip 7: Conditioning Regimen: Implement a regular conditioning schedule using a high-quality leather conditioner specifically designed for aged leather to maintain suppleness and prevent cracking.

Tip 8: Repair Expertise: Should repairs be necessary, seek a leather artisan specializing in vintage restoration to ensure the work is performed with appropriate techniques and materials.

Adhering to these principles ensures the enduring quality and aesthetic appeal of these heritage leather garments. Preserving these items necessitates a dedicated approach to maintenance and repair.

The subsequent sections will examine aspects of this manufacturers classic leather outerwear on market value, collection and fashion statement.

1. Material composition

The selection and treatment of leather are fundamental determinants of a Wilson’s Leather Jacket Vintage’s characteristics, influencing its durability, aesthetic appeal, and overall value. Understanding the composition of the leather is crucial for assessing condition and determining appropriate preservation methods.

- Type of Hide

The specific animal from which the hide originates significantly impacts the jacket’s properties. Cowhide, a common choice, offers robustness and resilience. Sheepskin provides a softer, more supple texture, often favored for comfort. Goatskin combines durability with a finer grain. The rarity and inherent qualities of the hide directly influence the jacket’s perceived value and suitability for particular climates or uses.

- Tanning Process

The method employed to transform raw animal hide into leather defines its stability and aging characteristics. Vegetable tanning, an older technique utilizing natural tannins, produces leather that darkens and develops a patina over time. Chrome tanning, a more modern process, yields a softer, more pliable leather with greater water resistance. Identifying the tanning process is essential for selecting appropriate cleaning and conditioning treatments.

- Finish and Coating

Applied finishes influence the leather’s appearance, texture, and protective qualities. Aniline finishes, using soluble dyes, showcase the natural grain of the leather, resulting in a rich, transparent color. Semi-aniline finishes incorporate a small amount of pigment to enhance color consistency. Corrected grain leather undergoes surface treatment to remove imperfections and create a uniform appearance. The type of finish affects the leather’s susceptibility to wear and tear and the effectiveness of cleaning products.

- Lining Materials

While not strictly part of the leather composition, the lining plays a crucial role in comfort and garment structure. Common lining materials include nylon, polyester, and acetate. Vintage jackets may feature rayon or cotton linings. The condition of the lining impacts the overall wearability of the jacket and can indicate the level of care it has received over time. Deteriorated linings often necessitate replacement to restore the jacket to its original condition.

These compositional factors collectively define the character and longevity of these items. A thorough understanding of the materials used in its construction is crucial for responsible ownership, preservation and appraisal within the context of vintage garments.

2. Era of Production

The period in which a specific leather jacket was manufactured significantly influences its design, materials, construction techniques, and ultimately, its desirability as a vintage item. Establishing the production era is essential for assessing its authenticity, value, and appropriate care requirements.

- Design Archetypes

Each decade exhibits distinct stylistic trends. Jackets from the 1970s may feature wide lapels and a slim fit, reflecting the prevalent fashion of the time. Conversely, 1980s jackets might incorporate padded shoulders and bolder silhouettes. Recognizing these period-specific design cues aids in accurate dating and authentication.

- Material Sourcing and Manufacturing Practices

The availability and utilization of specific materials and manufacturing techniques varied across different eras. Jackets produced prior to widespread adoption of synthetic linings may utilize natural materials like rayon or cotton. The prevalence of automated manufacturing processes in later decades influenced construction quality and consistency. These differences are crucial in evaluating the overall quality and authenticity of each garment.

- Hardware and Fasteners

The type and style of zippers, snaps, and buttons provide valuable clues to the jacket’s age. Early jackets may feature brass zippers from manufacturers like Talon or Crown. Later models might incorporate plastic zippers or alternative fastening systems. Specific hardware designs are often associated with particular manufacturers and time periods, serving as reliable indicators of production era.

- Labeling and Branding

Changes in company logos, labeling styles, and care instructions offer important insights into a jacket’s age. Early labels may feature woven designs and minimal information, while later labels often include detailed material compositions and care instructions. Examining the label design and content assists in establishing a more precise date of manufacture.

The interplay of design archetypes, material sourcing, hardware choices, and labeling practices culminates in a distinct character for each jacket based on its era of production. Discernment of these factors is pivotal for collectors, appraisers, and individuals seeking to preserve their vintage leather outerwear.

3. Hardware details

The specific components integrated into these garments serve as critical indicators of authenticity, production era, and overall quality. These seemingly minor elements provide valuable insight into the jacket’s history and construction.

- Zipper Mechanisms

Zipper brands, materials, and designs represent a significant aspect of garment identification. Early jackets frequently feature metal zippers manufactured by Talon or YKK, identified by distinct pull tab designs and manufacturing markings. Subsequent models may incorporate plastic zippers, which, while lighter, often exhibit reduced durability. Analyzing the zipper type offers a definitive clue to the jacket’s period of origin.

- Snap Fasteners

Snap fasteners, typically employed on pockets, cuffs, and epaulets, vary in design and construction. Vintage jackets may feature solid brass snaps or those bearing the manufacturer’s logo. The presence of corrosion or wear on these components can provide information about the garment’s age and usage history. The presence of specific logos or markings is indicative of particular production periods.

- Buckles and Adjusters

Buckles, often used on waist belts or side adjusters, are constructed from various materials, including brass, steel, or plastic. The style and finish of these components align with the design aesthetic of the jacket’s era. The type of buckle used also correlates to the overall quality of the item. Corrosion on metal buckles is a potential signal of age.

- Linings and Stitching

The type of material that is used as linings will dictate its vintage or modern construction. The use of cotton and rayon are typically for older “wilsons leather jacket vintage” whereas the newer constructed linings were primarily nylon and polyester.

The comprehensive assessment of these hardware elements in totality allows for a more accurate evaluation of origin and authenticity, as well as providing guidance on appropriate restoration techniques.

4. Seam Construction

Seam construction, encompassing the techniques and materials used to join pieces of leather, is a critical factor in assessing the durability, aesthetics, and authenticity of a legacy garment. Examination of seam construction details offers significant insights into its manufacturing era, production quality, and overall condition. For these items, variations in stitch type, thread composition, and edge finishing provide clues to its history and potential longevity. The presence of single-needle stitching, for example, often denotes an older construction method, whereas double-needle stitching signifies more modern manufacturing practices. Thread type, whether cotton or synthetic, similarly reflects the period of production. Reinforced seams in high-stress areas, such as shoulder seams and armholes, indicate a higher level of craftsmanship and contribute to increased garment lifespan. These elements are particularly relevant in distinguishing authentic vintage pieces from contemporary reproductions.

Variations in seam finishing techniques also reveal details about manufacturing standards. Raw edges, while sometimes employed for stylistic purposes, are more susceptible to fraying and damage. Turned and stitched edges, or the use of binding, provide a cleaner, more durable finish, indicative of higher-quality production. Careful observation of the stitch density, measured in stitches per inch, offers further insight into the precision and care taken during manufacturing. Higher stitch density generally translates to a stronger, more resilient seam. The absence of skipped stitches or uneven seam allowances suggests a higher level of quality control during production. Examination of the seam construction at stress points, such as pockets and closures, can reveal the garment’s history of use and any past repairs. Evidence of amateur repairs or poorly executed alterations negatively impacts its value and structural integrity. Authentic vintage jackets will often display characteristic wear patterns at these points, which, while not necessarily detracting from their appeal, should be carefully assessed for potential future maintenance needs.

Understanding seam construction provides a practical means for evaluating the condition and authenticity of legacy leather jackets. Careful inspection of stitching, edge finishing, and reinforcement details informs purchasing decisions, assists in proper care and preservation, and contributes to a more informed appreciation of these garments as historical artifacts. Preservation of these pieces depends on recognizing and addressing potential weaknesses in the seam construction.

5. Lining Condition

The internal textile component of a vintage leather jacket significantly influences its overall condition, wearability, and value. Deterioration of the lining, often due to age, usage, or improper storage, can compromise the garment’s structure and hygiene, affecting its comfort and longevity. The lining serves as a protective layer, shielding the leather from direct contact with skin and clothing, absorbing moisture and preventing abrasion. A compromised lining can expose the leather to damaging elements, accelerating wear and tear. For example, a disintegrated lining may shed fibers that adhere to the leather’s surface, necessitating specialized cleaning to remove. Furthermore, tears or holes in the lining can snag on clothing, reducing wearability and potentially causing further damage to both the lining and the leather exterior.

The material composition of the lining, typically cotton, rayon, or synthetic blends, dictates its susceptibility to specific types of damage. Cotton linings, common in older jackets, are prone to mildew and insect damage if stored improperly. Synthetic linings, while more resistant to these issues, may degrade due to exposure to sunlight or prolonged contact with body oils. Signs of deterioration include discoloration, stiffness, fraying, and unpleasant odors. Repairing or replacing a damaged lining can be a complex and costly process, requiring specialized skills and materials. Failure to address lining issues can lead to more extensive and expensive repairs later, potentially diminishing the item’s historical or monetary value. A meticulously maintained or professionally restored lining enhances the garment’s appeal and marketability, preserving its structural integrity and providing a comfortable wearing experience.

In summary, the state of the lining is an integral aspect of these vintage leather garments, influencing their condition, value, and usability. Addressing lining issues promptly through appropriate cleaning, repair, or replacement is crucial for maintaining the garment’s long-term integrity and ensuring its continued enjoyment. Challenges in assessing lining condition include hidden damage and sourcing matching replacement fabrics. Understanding the interplay between lining material, construction, and environmental factors contributes to the responsible stewardship of these aged garments.

Frequently Asked Questions

The following addresses common inquiries regarding the acquisition, care, and preservation of leather outerwear manufactured by Wilsons during earlier periods.

Question 1: How can the authenticity of a claimed “Wilsons Leather Jacket Vintage” be verified?

Verification involves meticulous examination of labels, hardware, and stitching patterns. Compare these features against known characteristics of jackets produced during specific eras. Consult reputable resources on vintage apparel authentication.

Question 2: What are the primary factors influencing the valuation of “Wilsons Leather Jacket Vintage”?

Valuation hinges on condition, rarity, design, and historical significance. Jackets in excellent condition, featuring desirable designs from significant periods, command higher prices. Provenance can also enhance value.

Question 3: What is the optimal method for cleaning “Wilsons Leather Jacket Vintage”?

Professional leather cleaning is strongly advised. Avoid home cleaning methods, as these can damage the leather. Select a cleaner experienced in handling vintage leather garments.

Question 4: How should “Wilsons Leather Jacket Vintage” be stored to prevent deterioration?

Store the jacket in a cool, dry environment away from direct sunlight and heat sources. Use a padded hanger to maintain its shape. Consider using a breathable garment bag for added protection.

Question 5: What steps should be taken to address cracking or stiffness in “Wilsons Leather Jacket Vintage”?

Leather conditioning, performed by a professional, can help restore suppleness. In severe cases, specialized leather restoration treatments may be necessary. Consult a leather artisan experienced in vintage garment repair.

Question 6: Can damaged zippers or linings on “Wilsons Leather Jacket Vintage” be repaired or replaced?

Yes, repairs and replacements are possible. Seek a leather artisan skilled in vintage garment restoration. Ensure that replacement parts are historically accurate and compatible with the jacket’s original design.

Proper care and preservation are critical for maintaining the value and extending the lifespan of these historical items.

The subsequent section will provide information about how to care “wilsons leather jacket vintage”.

Preserving the Legacy of Wilsons Leather Jacket Vintage

This exploration of “Wilsons Leather Jacket Vintage” has underscored the importance of understanding the garment’s material composition, era of production, hardware details, seam construction, and lining condition. Careful attention to these elements is essential for authenticating, valuing, and preserving these historical pieces. The distinct attributes of each jacket, shaped by the manufacturing processes and design trends of its time, contribute to its unique character and collectibility.

Continued diligence in the proper care, storage, and restoration of these heritage items will ensure their longevity and preserve their historical significance for future generations. Recognizing the value of “Wilsons Leather Jacket Vintage” extends beyond its monetary worth; it represents a tangible connection to the past and a testament to enduring craftsmanship.