Components utilized in older, typically pre-20th-century, kerosene or oil-fueled lighting devices are the focus. These elements often include burners, wicks, chimneys, fonts (reservoirs), collars, and shades. For example, a brass burner with intricate detailing is a key identifying feature, along with a hand-blown glass chimney. These elements, when complete, provided a crucial source of light before widespread electrification.

Preserving these items provides a tangible connection to the past, offering insight into historical lighting technologies and manufacturing practices. Authentic replacement components are vital for restoring antique lamps to their original functional condition, maintaining both aesthetic and historical value. The availability and proper utilization of these components are essential for collectors and enthusiasts seeking to preserve and display these artifacts.

The subsequent discussion will address the common materials used, methods for identification, sources for acquiring replacement pieces, and best practices for their safe and effective application in restoration projects.

Essential Guidance for Antique Lamp Components

The following represents critical advice for those involved with the acquisition, assessment, or utilization of constituent elements from antiquated oil-fueled luminaries.

Tip 1: Accurate Identification is Paramount: Prioritize precise identification of a component’s origin and compatibility. Consult catalogs or reference materials specific to vintage lighting to ensure accurate matching of parts.

Tip 2: Prioritize Material Compatibility: When replacing a component, ensure the new part is constructed of a material consistent with the original lamp’s design. Mixing incompatible metals can lead to corrosion or structural weakness.

Tip 3: Exercise Caution During Cleaning: When cleaning acquired pieces, avoid harsh chemicals or abrasive materials. Gentle cleaning methods, such as warm water and mild soap, are preferred to prevent damage to delicate surfaces or finishes.

Tip 4: Verify Wick Functionality: Examine wicks for proper capillary action. A dry or brittle wick will not effectively draw fuel, impeding the lamp’s functionality. Replace wicks showing signs of degradation.

Tip 5: Inspect Burner Integrity: Thoroughly inspect the burner assembly for cracks, corrosion, or damage to the threads. A compromised burner can lead to fuel leaks or uneven combustion.

Tip 6: Ensure Chimney Compatibility: Confirm the chimney is correctly sized and designed for the specific burner. An incompatible chimney will negatively impact airflow and potentially cause incomplete combustion or soot buildup.

Tip 7: Preserve Original Finishes: Attempt to preserve original finishes whenever possible. Refinishing can diminish the historical value of a component. Gentle cleaning is often sufficient to restore its appearance.

The diligent application of these practices supports the longevity and authentic preservation of antique lighting devices.

The subsequent section will detail specific resources and methods for sourcing and maintaining these historical artifacts.

1. Burner Assembly

The burner assembly stands as a critical element within the system of antiquated oil-fueled lamps. Its functionality directly impacts the efficiency of combustion and the overall illumination provided by the lighting device. Examination of burner assemblies offers insight into the lamp’s age, design, and intended use.

- Wick Adjustment Mechanisms

The mechanism for adjusting the wick’s height, typically a rotating knob or lever, controlled the amount of fuel exposed to the flame. Intricate designs featuring gears or ratchets indicated a higher quality lamp. Failures in this mechanism rendered the burner ineffective, requiring repair or replacement to restore functionality. Threads must be inspected carefully to ensure smooth operation.

- Airflow Regulation Design

Burners were designed with specific air intake structures to ensure sufficient oxygen supply for complete combustion. These designs varied widely, influencing flame shape and reducing soot production. Blocked or damaged air inlets compromised combustion, leading to incomplete burning and potential hazards. Some early designs could be dangerous due to poor airflow, and were quickly changed.

- Material Composition and Corrosion

Burner assemblies were typically constructed from brass, iron, or a combination of metals. Brass offered corrosion resistance but could be susceptible to deformation. Iron burners, while durable, were prone to rust. Corrosion weakens the structural integrity, leading to fuel leaks or burner failure. Identification of the metal type is critical for proper cleaning.

- Flame Spreader Functionality

A flame spreader is situated above the wick and disperses the flame, producing a broader, more even light output. Different shapes and designs are observed across various burner types. A damaged or missing flame spreader diminishes light quality. The flame spreader also stabilized the flame by allowing the gasses from the burner to be burned safely.

Understanding burner assembly features provides valuable insights into the technological evolution of antiquated oil-fueled luminaries. The nuances in their design, materials, and functionality reflect innovations intended to maximize light output, improve safety, and enhance longevity. Detailed inspection can help ensure safe restoration and usage.

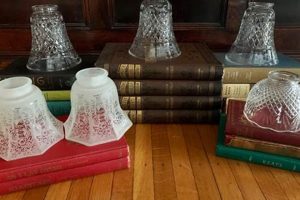

2. Glass Chimney Styles

Glass chimney styles, as a constituent element, profoundly influenced the functional efficacy and aesthetic attributes of vintage oil lamps. The design of the glass chimney exerted a direct effect on the lamp’s combustion process, airflow dynamics, and light projection. Variations in shape, height, and glass composition resulted in distinctive flame characteristics and illumination patterns. For example, a tall, narrow chimney promoted a stronger updraft, facilitating more complete combustion and a brighter, more concentrated light. Conversely, a shorter, wider chimney allowed for greater air circulation, reducing soot production and producing a softer, diffused light. Specific historical examples include the “Bulge” chimney which was designed to keep the chimney from tipping due to it’s wider base. And the Victorian era saw highly decorated and elaborate etched glass chimney designs reflecting the style of the time. The selection of a proper chimney style represents a significant consideration during the restoration of antique lamps, necessitating careful attention to burner compatibility and intended lighting effect.

The practical significance of understanding glass chimney styles extends beyond mere aesthetic considerations. The appropriate chimney selection directly impacts the lamp’s safety and operational performance. A mismatched chimney could restrict airflow, leading to incomplete combustion and potentially dangerous carbon monoxide emissions. Furthermore, an ill-fitting chimney could be prone to cracking or shattering due to thermal stress. Consequently, informed selection requires a thorough understanding of the lamp’s design parameters, burner type, and fuel source. Collectors and restorers often consult historical catalogs and lighting manuals to determine the correct chimney style for a particular lamp model.

In summary, glass chimney styles represent an integral element within the broader context of vintage oil lamps, exhibiting a cause-and-effect relationship with both the lamp’s functionality and its aesthetic appeal. Correct identification and application of chimney styles are crucial for ensuring safe operation, optimal performance, and the preservation of these historical artifacts. Challenges remain in sourcing original or accurately reproduced chimneys, particularly for rare or obscure lamp models. Further research into the nuances of chimney design and manufacturing practices is warranted to support informed restoration efforts and to preserve the legacy of these lighting technologies.

3. Font Material Variances

Font material variance directly influences the safety, longevity, and operational characteristics of “vintage oil lamp parts.” The font, or reservoir, designed to hold the fuel supply, was historically constructed from a range of materials, each with distinct properties that affected its suitability. Glass fonts, for example, permitted visual monitoring of fuel levels and offered resistance to corrosion from kerosene, however, they were inherently fragile and susceptible to breakage from impact or thermal stress. Metal fonts, typically brass, tin, or iron, provided increased durability but required protective linings to prevent fuel leakage and corrosion. Ceramic fonts, less common but present in some models, combined aesthetic appeal with moderate durability, although they were prone to cracking if exposed to rapid temperature changes. The choice of material reflected a trade-off between cost, manufacturing ease, aesthetic considerations, and practical performance requirements.

The implications of font material selection extend beyond basic functionality. A failing font can be a fire hazard. For example, the presence of rust within a metal font, often stemming from prolonged exposure to moisture, could compromise the integrity of the fuel seal, resulting in leaks and potential ignition sources. Similarly, undetected cracks in a glass font might lead to fuel seepage, creating a dangerous situation. Restorers of “vintage oil lamp parts” must therefore carefully assess the font material for signs of degradation and apply appropriate conservation techniques, such as relining metal fonts or carefully repairing minor chips in glass fonts. The composition of the font determines the appropriate cleaning and repair methods required to prevent damage and ensure safe future operation.

In summary, understanding font material variances represents a critical aspect of working with “vintage oil lamp parts.” The choice of material directly impacts durability, safety, and required maintenance procedures. Restoration efforts must consider the properties of the font material to ensure long-term preservation and prevent potential hazards. The inherent challenges lie in accurately identifying the original material composition and employing compatible repair techniques to maintain the lamp’s structural integrity and historical authenticity.

4. Wick Composition Details

Wick composition details represent a crucial yet often overlooked element within the broader context of “vintage oil lamp parts.” The type of material used to construct the wick directly impacts the lamp’s fuel consumption rate, flame quality, and overall operational efficiency. Predominantly, antique oil lamps utilized wicks crafted from either cotton or linen fibers. Cotton wicks, known for their high absorbency, facilitated a consistent and readily controllable flame, making them a common choice for general-purpose lamps. Linen wicks, characterized by their greater tensile strength and slower burning rate, were often favored in lamps requiring sustained illumination over extended periods. The specific weave pattern and thickness of the wick further influenced fuel delivery, thereby modulating flame intensity and duration. For instance, a tightly woven, thicker wick would draw more fuel than a loosely woven, thinner counterpart, resulting in a brighter but potentially less stable flame. Therefore, selection of appropriate wick material, dimensions, and construction was integral to achieving optimal lamp performance and preventing issues such as excessive smoking or fuel starvation.

The practical significance of understanding wick composition extends to the restoration and maintenance of “vintage oil lamp parts.” Replacing a deteriorated wick with an incompatible material can compromise the lamp’s functionality and potentially create safety hazards. Using a synthetic wick in a lamp designed for natural fibers, for example, could lead to incomplete combustion and the release of harmful fumes. Moreover, improper wick trimming or installation can obstruct airflow, resulting in an uneven flame and increased soot production. Antique lighting manuals and historical texts provide valuable guidance on identifying appropriate wick materials and proper maintenance techniques for various lamp designs. Careful attention to these details ensures the continued safe and efficient operation of these historical artifacts.

In summary, wick composition details are intrinsically linked to the overall performance and preservation of “vintage oil lamp parts.” Material selection, weave pattern, and dimensions directly influence fuel delivery, flame quality, and combustion efficiency. Understanding these nuances is essential for restorers and collectors seeking to maintain the authenticity and functionality of antique oil lamps. While sourcing historically accurate wick materials may present challenges, the benefits of doing so far outweigh the risks of using inappropriate substitutes. Further research into historical manufacturing practices and experimental analysis of various wick compositions could yield valuable insights for preserving these important artifacts.

5. Shade Attachment Methods

Shade attachment methods represent a critical design aspect of “vintage oil lamp parts,” impacting both the aesthetic presentation and functional performance of these lighting devices. The means by which a shade is affixed to an oil lamp directly influences the distribution of light, the stability of the lamp, and the overall visual character. Varied approaches to shade attachment reflect evolving design sensibilities and technological innovations across different historical periods.

- Collar and Gallery Systems

Collar and gallery systems represent a common method for securing shades to “vintage oil lamp parts.” A metal collar, typically made of brass or iron, is affixed to the burner assembly. A separate gallery, often ornate in design, then rests upon the collar, providing a stable platform for the shade. Tension springs or screws within the gallery ensure a secure fit, preventing the shade from dislodging. This system was prevalent in Victorian-era lamps, where elaborate glass or fabric shades were frequently employed to diffuse and soften the light. The collar and gallery system is easily adjustable for varying shade heights.

- Friction Fit Designs

Friction fit designs rely on the pressure exerted by the shade itself to maintain its position on the lamp. Typically, the shade features a flared base or a recessed rim that snugly fits over the burner assembly or a specially designed support structure. The inherent simplicity of this approach made it a cost-effective solution for mass-produced lamps. However, friction fit systems are susceptible to instability if the shade is improperly sized or if the supporting structure becomes worn or damaged over time, leading to potential safety hazards. Certain types of glass can easily break from the pressure of these types of system.

- Spider and Finial Arrangements

Spider and finial arrangements involve the use of a wire framework, known as a spider, to support the shade. The spider typically consists of multiple arms that extend from a central ring, which sits atop the burner assembly or a supporting collar. A decorative finial, often made of glass, metal, or ceramic, is then screwed onto a threaded rod extending through the center of the spider, securing the shade in place. This method provided a versatile means of accommodating a wide range of shade shapes and sizes, making it popular in lamps designed for both functional and decorative purposes. Spider and finial designs were popular where the lamps were mass produced to ensure a perfect fit of the shades.

- Integrated Shade Holders

Some “vintage oil lamp parts” feature integrated shade holders as part of their original design. These holders are typically molded or cast directly into the lamp’s font or burner assembly, providing a seamless and aesthetically pleasing means of attaching the shade. Integrated holders often take the form of raised ridges or grooves that engage with the shade’s rim, or threaded sockets that accommodate a shade-supporting ring. This approach offered a high degree of stability and security but limited the interchangeability of shades, as only those specifically designed for the lamp could be used. The design required a high level of skill to produce.

These various shade attachment methods each reflect specific design considerations and manufacturing capabilities prevalent during different periods in the history of “vintage oil lamp parts.” Understanding these nuances is critical for proper restoration and preservation, ensuring that replacement shades are compatible with the original lamp design and that the lamps function safely and effectively.

Frequently Asked Questions Regarding Vintage Oil Lamp Components

The following addresses common inquiries concerning the identification, acquisition, and utilization of elements from antiquated oil-fueled lighting devices. Careful consideration of these points aids in the safe and authentic preservation of these artifacts.

Question 1: How can one definitively determine the age of a specific constituent element?

Establishing the precise age involves scrutinizing manufacturing markings, patent dates, and material composition. Consulting historical catalogs and antique lighting reference guides facilitates accurate dating based on known production periods.

Question 2: What measures should be implemented when cleaning potentially fragile components?

Gentle cleaning methods are paramount. Employ lukewarm water with mild, non-abrasive detergents. Avoid harsh chemicals or excessive scrubbing, as these can damage delicate surfaces or finishes.

Question 3: Where are reliable sources to acquire authentic replacement parts?

Specialty antique lighting dealers, reputable online auction platforms, and estate sales frequently offer original or accurately reproduced components. Prioritize vendors with established reputations for authenticity.

Question 4: What are the critical safety considerations when utilizing components of unknown origin?

Thorough inspection is imperative. Examine for cracks, corrosion, and structural weaknesses. Pressure testing fuel fonts and ensuring burner integrity minimizes the risk of leaks or combustion hazards.

Question 5: What is the most appropriate methodology for storing components not immediately required?

Store components in a dry, climate-controlled environment, shielded from direct sunlight and extreme temperature fluctuations. Individual wrapping in acid-free paper protects against scratches and dust accumulation.

Question 6: How can one distinguish between original parts and later reproductions?

Original components often exhibit subtle manufacturing imperfections or wear patterns absent in modern reproductions. Close examination of material quality, construction techniques, and the presence of original markings aids in differentiation.

Proper understanding and application of these guidelines will ensure a safer and more authentic experience when working with antique lighting elements.

The subsequent discussion will delve into specific restoration techniques for common component types.

Conclusion Regarding Vintage Oil Lamp Parts

The preceding analysis has illuminated the intricacies associated with “vintage oil lamp parts,” encompassing materials, styles, and functional considerations. Accurate identification, proper maintenance, and informed restoration techniques are paramount for preserving these artifacts of historical lighting technology. The variety of components, from burners to shades, underscores the complex engineering and design involved in pre-electric illumination.

Continued research and diligent application of established preservation practices are essential to safeguard the tangible legacy represented by “vintage oil lamp parts.” These efforts ensure that future generations can appreciate the ingenuity and craftsmanship inherent in these historical objects. Understanding of these parts contributes to the preservation of not just objects, but of a history of lighting itself, offering insight into past lives.